If readers are noticing a trend in dental and tooth-related 3D printing news this week, that’s because the ongoing International Dental Show in Cologne, Germany is proving to be a hotbed for dental 3D printing innovations. A showcase for the latest in dental technologies, the IDS is hosting 3D printing companies such as EnvisionTEC, which introduced its new E-IDB dental 3D printing material, and Natural Dental Implants AG, which has just unveiled a 3D printed REPLICATE Tooth at the expo.

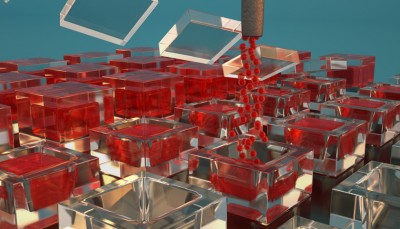

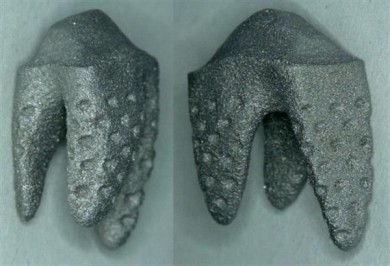

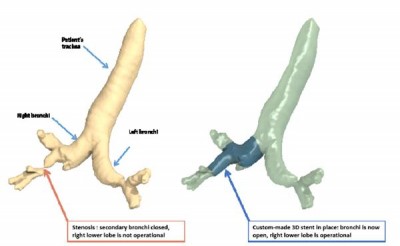

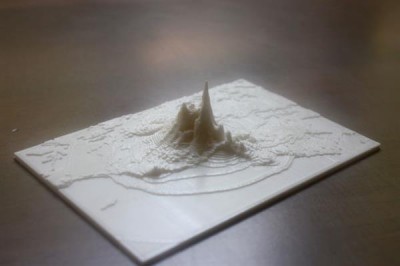

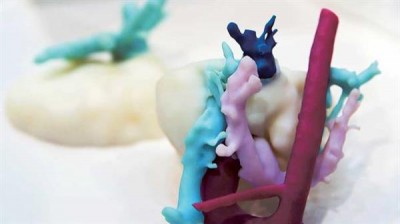

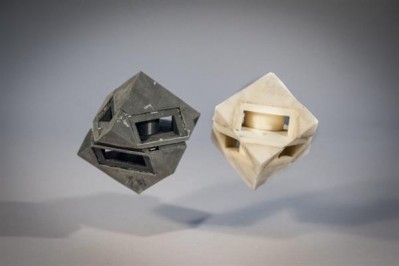

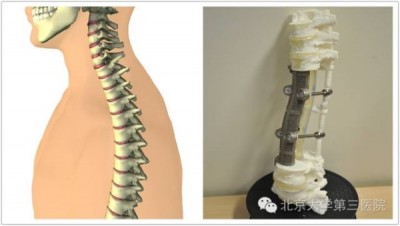

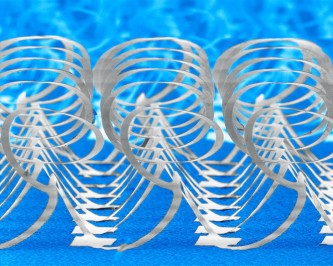

Natural Dental Implants (NDI) has been filing patents for its innovative REPLICATE Tooth system as early as 2006, with its current commercially available version of it made using 5-axis CNC milling. Its newest prototype version of the REPLICATE Tooth, which is made from a titanium root portion and a zirconia abutment segment, was made using 3D printing technologies.

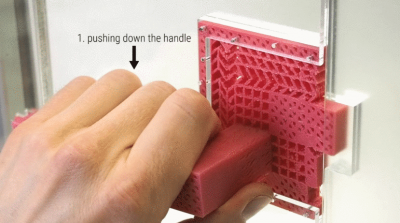

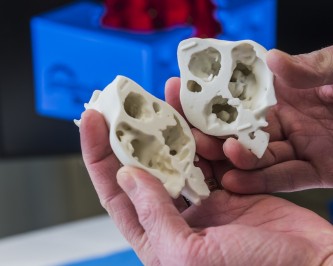

NDI’s REPLICATE Tooth system is designed so that patients can have teeth replaced easily with artificial ones that are custom fit to their mouth. As the company explains on its website, to receive its specialized tooth implants, patients need only to have a 3D X-ray taken of their mouth, which a customized replica of the affected tooth is then based on.

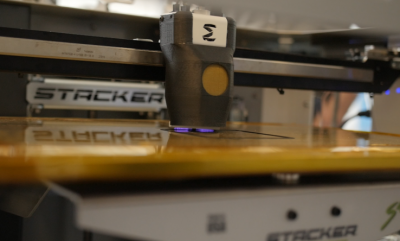

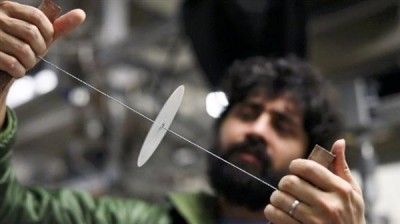

The replica tooth, made using CNC milling and now also with 3D printing technologies, can be inserted into the patient’s mouth as soon as their real tooth is removed, making for a seamless and simple transition that removes the necessity for more drilling. A REPLICATE Temporary Protective Crown is placed on top of the new tooth and bonded to a neighbouring tooth until it becomes secure in the mouth.

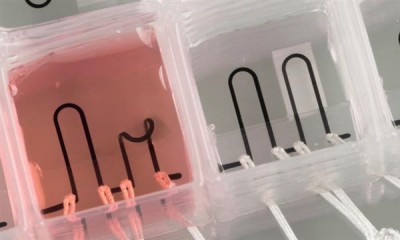

NDI's REPLICATE Tooth bonded to a real tooth

Once properly implanted, the patient’s new artificial tooth is designed to become “strongly embedded” in the patient’s mouth thanks to a process of osseointegration. The REPLICATE Tooth requires about six months of healing time, after which it should exist in the patient’s mouth as their other teeth do.

Using 3D printing to create the newest REPLICATE Tooth implants is allowing NDI to keep making its custom products, but at a cheaper production cost. Currently, NDI has a working prototype for its 3D printed artificial tooth, which will undergo extensive testing later this year.

Ruedger Rubbert, CEO of NDI, commented on the new product, saying: “We started thinking about customized tooth replacement systems more than ten years ago. Our patent portfolio includes endossoeus and perio-integrative implementations, various surface enhancements, CAD/CAM systems, and manufacturing technologies, utilized in rapid prototyping methods and 3D printing. This enables industrialized and chair?side fabrication of individually shaped dental implants. Using new technologies like 3D printing helps us reduce costs and provide even more value to our customers.”

NDI is based in Berlin, Germany, and has operations through a subsidiary in Dallas, Texas. The company’s REPLICATE Tooth system is currently available in Europe, and could enter the U.S. market once it is approved by the FDA.