One of the most promising areas for desktop 3D printing is undoubtedly the development of new, innovative, and usually inexpensive assistive devices. In recent years, a number of maker challenges specifically geared towards 3D printable assistive devices have turned out some simple yet remarkably useful tools that can help disabled people with their day-to-day activities.

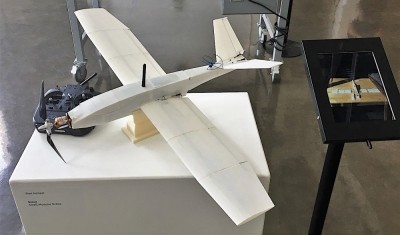

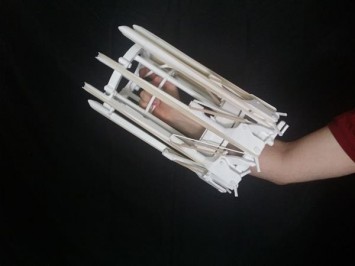

Though admittedly not as simple as many devices we've seen, the latest 3D printed assistive we’ve come across, a multifunctional walker, is one for the books. Designed by biomedical engineer Eliza Wrobel, the 3D printed walker device was developed to help partially disabled people regain more mobility around their homes and even outdoors.

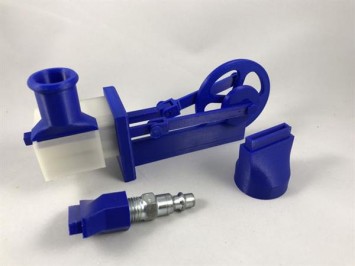

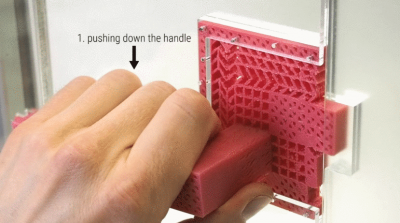

Wrobel’s device is no ordinary walker, however, as it integrates a number of features that allow its user to accomplish a wide range of tasks. These features include changeable add-ons such as a shopping cart and a baby seat (turning the walker into a stroller, of sorts), as well as a cup holder. More standard features include hand-activated brakes and regulated height.

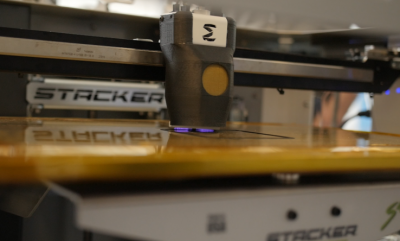

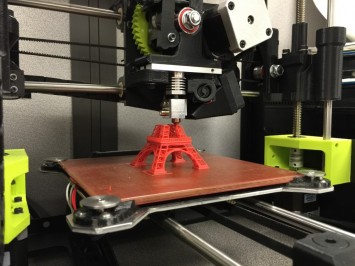

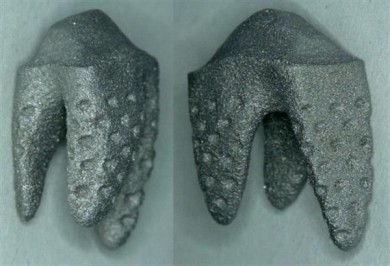

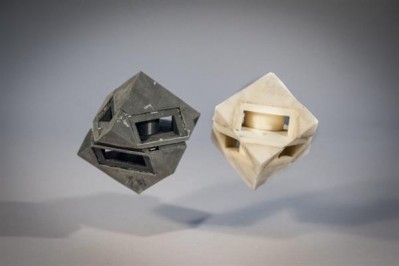

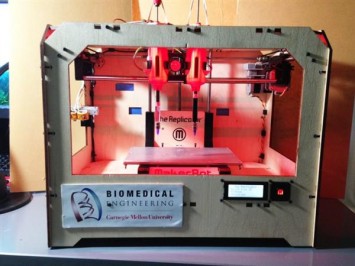

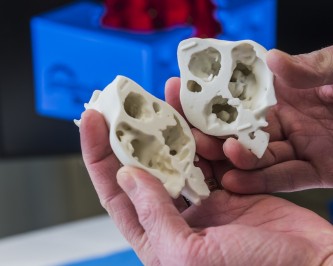

The 3D printed multifunctional walker is still being developed and prototyped by Wrobel, who will use the 1:2 scale prototype as a proof of concept for her innovative design. To construct the prototype, the engineer used a variety of 3D printed parts (made using a ZMorph 2.0 SX 3D printer) as well as a handmade cushion, wire, straps, and screws. In total, over 100 individual parts were used to construct the walker prototype.

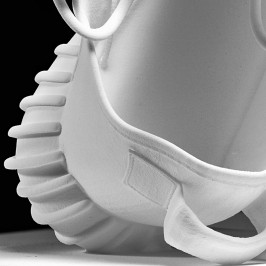

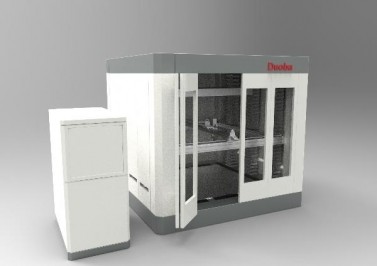

ZMorph 2.0 SX 3D printer

In terms of 3D printing materials used, 3D printing company ZMorph reports that Wrobel used Silver ABS for the walker’s frame, yellow and black PLA for parts that needed more support, and Flex filament, a black rubber-like material, for the wheels, brakes, and arm pads. The ZMorph 2.0 SX 3D printer used to fabricate the prototype is a multitool machine with a build volume of up to 250 x 235 x 165 mm that can accommodate over 30 different types of material.

While the current iteration of the 3D printed multifunction walker is a half-scale prototype, and a rather fragile-looking one, Wrobel has effectively shown her proof of concept, and can now pitch her innovative design for further support and development. If she does eventually build a full-scale, functional prototype of the multi-use assistive device, 3D printing would still be a more-than-viable option for manufacturing it. We'll just have to wait and see whether the impressive prototype is taken to the next level.