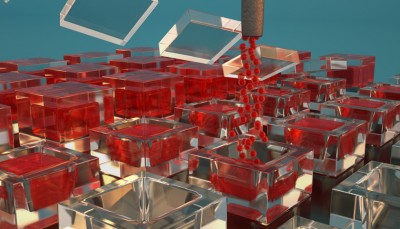

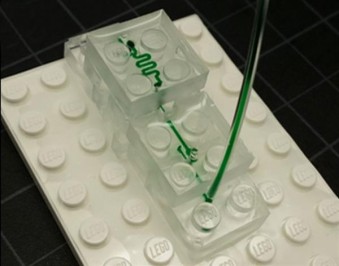

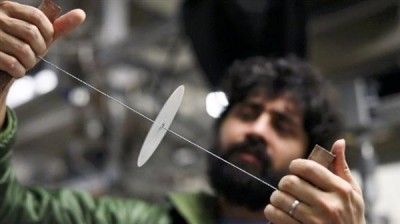

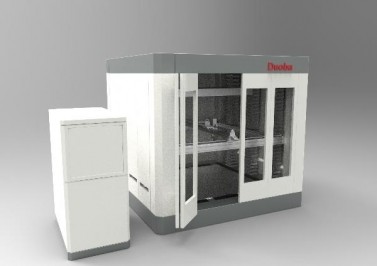

3D printing technologies are on the rise, with new additive manufacturing systems and materials being developed at astonishing rates. Now, Israeli company MICRON3DP is hoping to shatter 3D printing expectations with its innovative glass 3D printing. The company, which first announced its Glass 3D Printing technology last year, has just released some exciting news about how its technology is advancing. Specifically, MICRON3DP will soon be introducing a full high-resolution glass 3D printer.

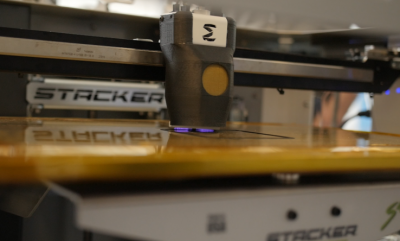

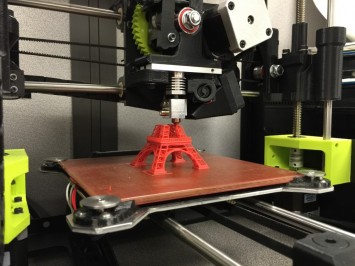

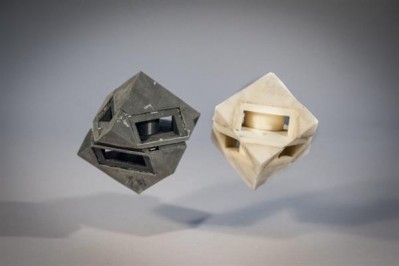

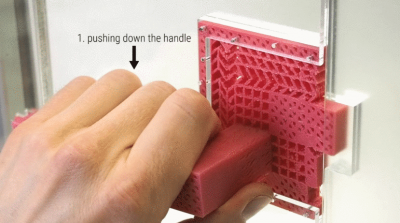

MICRON3DP’s glass 3D printer is based on an FFF (fused filament fabrication) technique which operates at much higher temperatures than its plastic 3D printer counterpart. That is because, in order to bring glass to a melting point, you need temperatures of at least 1000 degrees Celsius. Aside from the extreme temperature, achieving a fine resolution for glass 3D printing had been a distinct challenge for the Israeli glass printing company.

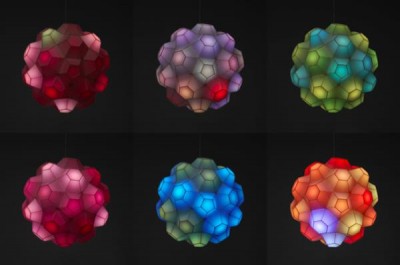

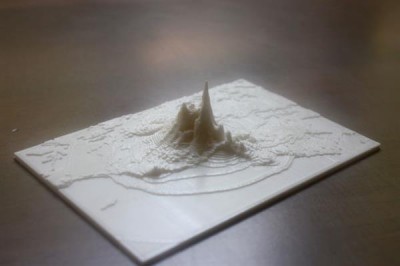

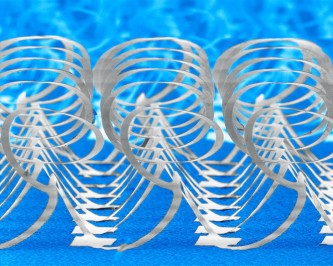

Finally, after much research and development, the company seems to have broken ground on this front and will be introducing a high-resolution glass 3D printer, capable of layer thicknesses of as little as 100 microns. With a respectable build volume of 200 x 200 x 200 mm, the additive manufacturing system is reportedly capable of printing in Soda-Lime and Borosilicate glass.

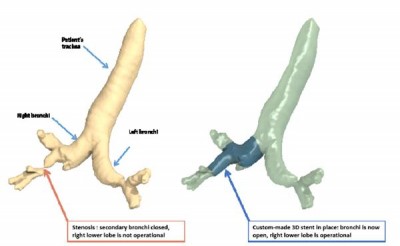

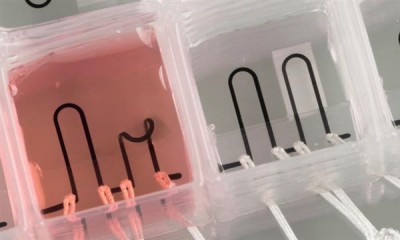

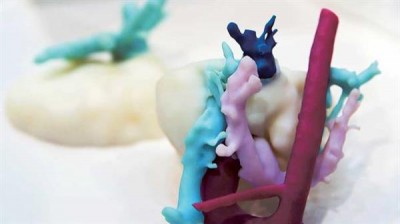

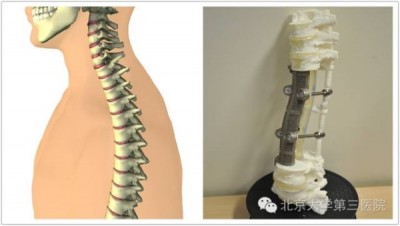

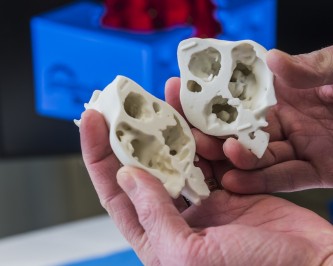

As a material, glass has many benefits, including strong chemical resistance, easy sterilization, and high temperature durability. In addition to these properties, glass is also a biocompatible material and, as we know, is an ideal material for transferring light. All of these properties culminate in a material that is extremely versatile, with applications in medicine, aerospace, security, architecture, and art.

One of the down-sides of using glass as a material, however, has been a lack of rapid prototyping methods for it. Not only would 3D printing glass offer a solution for rapid prototyping glass parts, but it would also offer advantages over other types of 3D printing, such as with powder materials. That is, because the technology utilizes molten glass, little post-processing would be needed once the print is complete.

Eran Gal-Or, CTO at MICRON3DP, said of the glass 3D printing tech: “We are constantly improving our glass 3D printing technology such that we are now able to print high resolution glass parts with a layer thickness as small as 100 microns.”

While the additive manufacturing company continues to work on and improve its high-resolution glass 3D printing, MICRON3DP CEO Arik Bracha is also inviting other innovators and engineers to get involved in the effort. “We are comfortable that there are any other ‘hot’ applications out there that we still have not reached and more will come now that the technology is working,” he commented. “We are encouraging engineers and artists to come forward with new applications.”