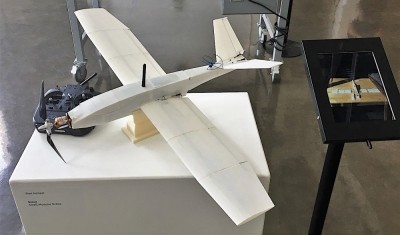

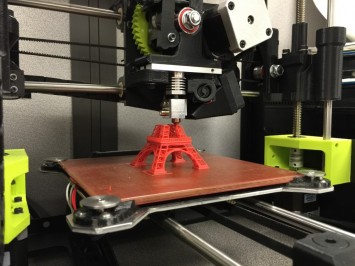

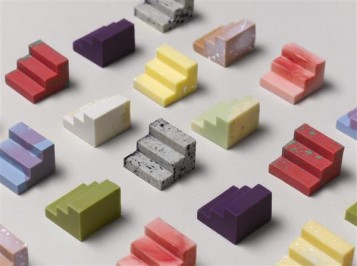

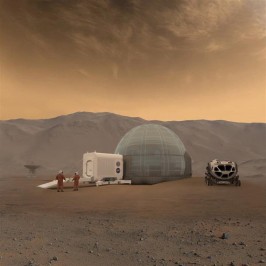

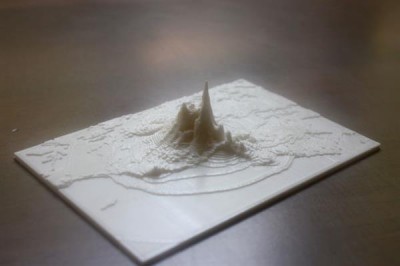

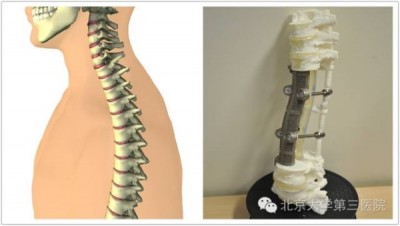

3D printing technology is being increasingly investigated as a way to develop the construction industry, with its huge potential for improved automation offering a vision of more efficient and imaginative building sites in the future, responding to some of the more demanding architectural problems around the world. The latest advance in this field took place recently in Denmark, as a major new dome structure was officially opened in Aarhus Harbour. Made using a concrete 3D printing technique, the structure is located at Copenhagen's pioneering Dome of Visions institute.

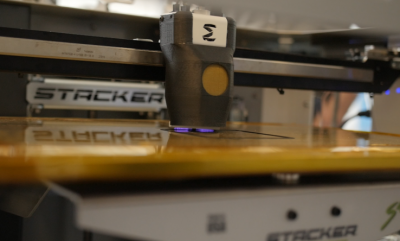

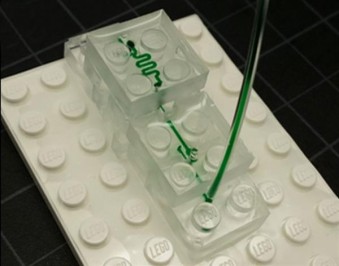

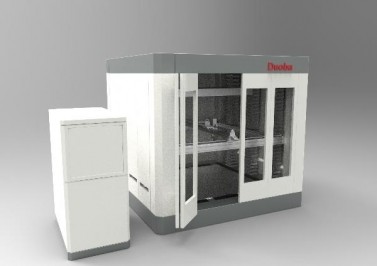

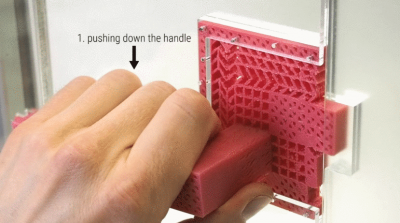

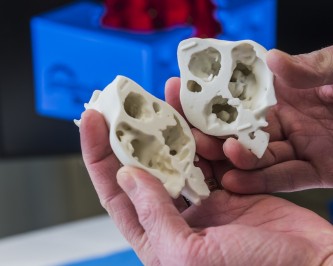

The dome, which is one of the first 3D printed concrete structures in the Scandinavian country, was the result of a major collaborative effort. The project was aimed primarily at exploring the possibilities that 3D printing presents for the construction industry and seeing how they could be better implemented. Architecture firm Kim Utzon Architects led the way, partnering with the Danish Technological Institute and NCC (Nordic Construction Company) Danmark.Production took place on a large concrete 3D printer at the Danish Technological Institute.

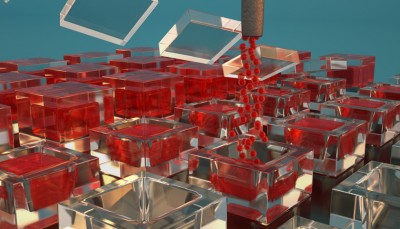

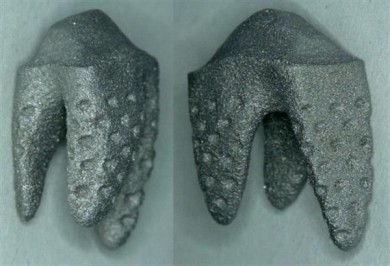

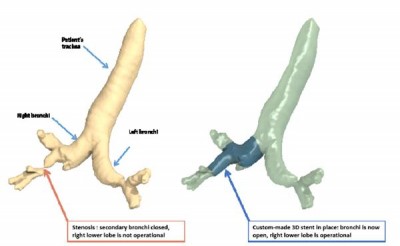

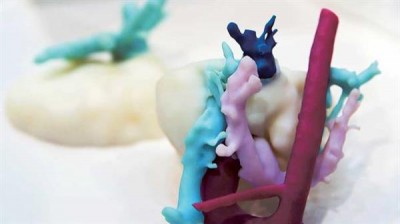

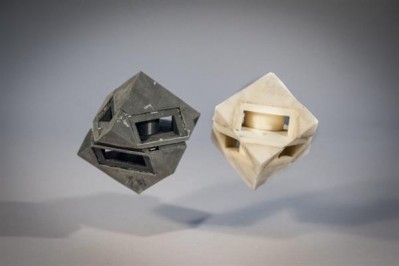

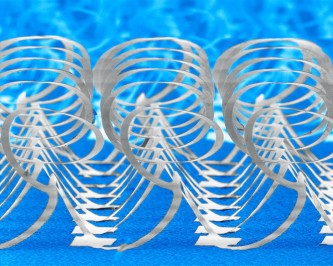

The dome structure, which is currently used as a form of urban furniture, is composed of several 3D-printed elements that have been tensioned on-site. This principle enables strong structures to be made with a minimum of material consumption. Development of this technique in other projects could lead to a huge increase in the cost-effectiveness of building work.

Traditionally, concrete is reinforced with steel after being poured to give it extra strength, but this technique isn’t entirely compatible with the 3D printing approach. Tensioning could point the way forward to increased implementation of 3D printing technology. The shells of the Sydney Opera House are a famous example of a structure produced using this same tensioning method.

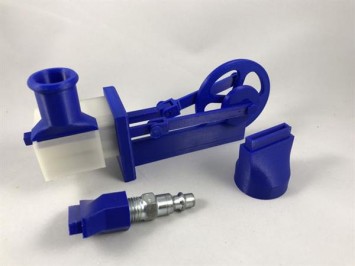

According to Thomas Juul Andersen, Senior Vice President, Technological Institute,"We are testing the possibilities that 3D printing can add to construction. Throughout the project we have tested some of the new architectural design freedoms and expressions that 3D printed concrete provides. At the same time, experience has been gained with both the printing technology and material composition. Experience has also been gained in transferring a digital design directly to the production of concrete elements.’’

"For many years, (we have) been working to increase the productivity of construction. Automated production can change over. In NCC we see a potential, in that parts of the building are automatically produced by robots while others are manually executed, and here 3D printed concrete is one of several options’’, says Anders Kudsk, Area Manager, Concepts and Innovation, NCC Danmark.

3D printed architecture may remain on the small scale of this dome structure, as it is still a mostly untested technique with some apparent limitations in its current state, but this situation could soon change. Introducing digital designs into the building process, as well as using 3D printing in exploratory projects in order to stimulate new ideas, could serve to modernize an industry whose methods tend to change at a relatively slow pace compared to other sectors. As the urban landscape starts to shift dramatically due to climate and population pressures, and digital technologies in other fields revolutionize the way people interact with their built environment, 3D printing technology’s innovations could prove to be very timely.