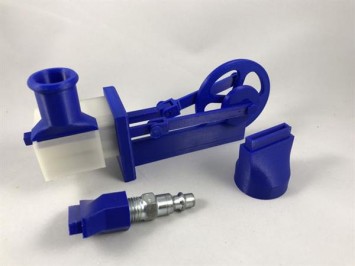

Mecaer Aviation Group (MAG), a leader in customizing high-end helicopter interiors, is using industrial 3D printers from Roboze to create end-use parts for its designs. The company is using advanced materials like PEEK for parts that will be installed on forthcoming helicopters.

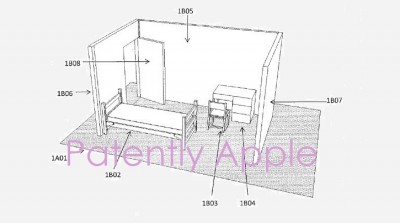

When working for luxury helicopter specialists like MAG, designers have to aim high. Sky-high, in fact. To create the most contemporary, comfortable, and stylish interiors, the company must ensure that it provides high-quality in-flight entertainment via modern computer, television, and sound systems, while also taking care of technical aspects like noise and vibration reduction, environmental control, and the presence of emergency medical systems. Most importantly, to perfect all aspects of the in-flight experience, MAG needs to utilize the most up-to-date production systems, 3D printers included.

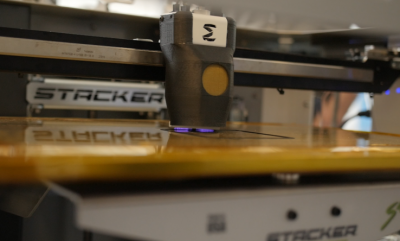

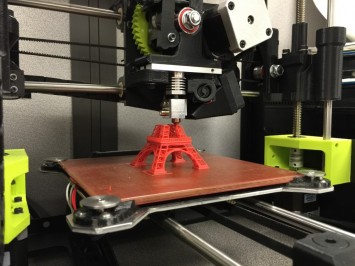

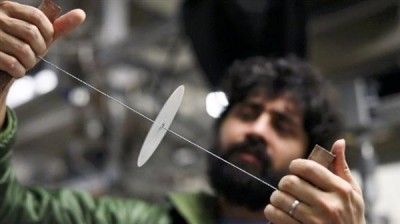

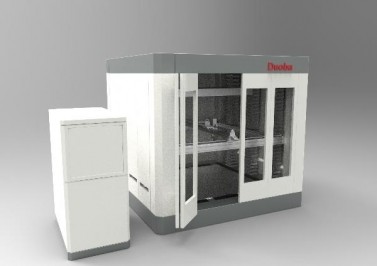

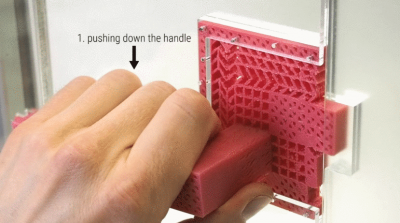

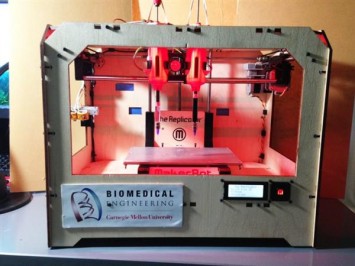

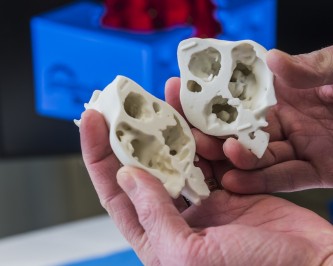

Although it already had a foothold in 3D printing for rapid prototyping and other purposes, MAG recently partnered with 3D printer manufacturer Roboze to acquire a number of Roboze One + 400 industrial 3D printers. With these machines, the Cabin Comfort division of the helicopter specialist has been able to create a number of important parts for its luxury helicopters interiors—not prototypes, but end-use parts that will be incorporated into future helicopters.

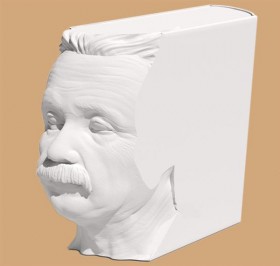

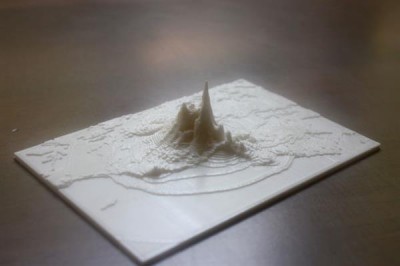

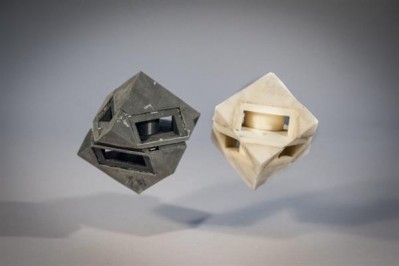

MAG is using 3D printers to create parts for its luxury helicopter interiors

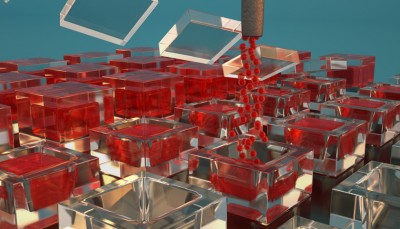

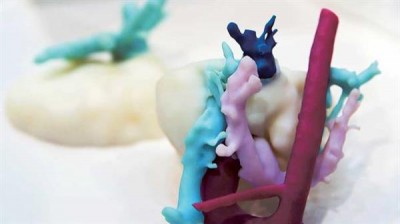

"We are not new in using 3D printers," explained Vincenzo Massarelli, part of the Cabin Comfort System division at MAG. “Until now [we] mainly used to validate the work of designers and have aesthetic conceptual models of different details of our own design. With the new Roboze One + 400 our company will become functional. We have already begun to print the finished products, not prototypes, but the final components printed in engineering plastics such as PEEK and PEI that will be installed directly (after a rigorous validation process) on our upcoming helicopters.”

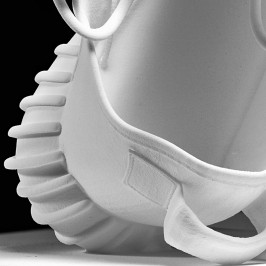

According to Roboze, the 3D printer manufacturer always expected to work with clients in aerospace, and even optimized various aspects of its machines to be most beneficial to those making parts for aircraft. “The aviation sector is of great interest for us,” admitted Alessio Lorusso, CEO of Roboze. “We designed the One + 400 to meet the needs of this market by investing a lot in R&D on the extrusion process for engineering plastics such as PEEK. We expect the aerospace & aviation industry will represent for us in the next five years an important and strategic business channel.”

Although neither MAG nor Roboze has specified which helicopter parts have been 3D printed using the Roboze 3D printers, Roboze will be showcasing some of those parts at next week’s formnext 3D printing trade show in Frankfurt, Germany.

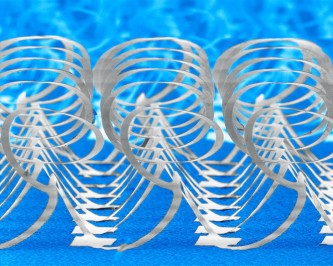

The Roboze One + 400 3D printer can print with advanced materials like PEEK, PEI, and Carbon PA