3D printing has become an increasing source of medical aid in earthquake-stricken Nepal. In the wake of the 7.8-magnitude earthquake that devastated the country in April 2015, killing almost 9,000 people, Nepalese communities have been struggling to survive.

Health clinics are largely overwhelmed and under-resourced. Local charities say that a series of complications including poor road infrastructure, a lack of finances, and slow bureaucracy means a lengthy supply-chain process. Additionally, as most of Nepal’s medical equipment is manufactured in China or India, local health clinics struggle to purchase any supplies that aren’t available in bulk.

Consequently, medical items taken for granted in Western hospitals, such as tweezers, fetoscopes, and otoscopes, can take up to three months to arrive to Nepalese clinics that need them. And for a country still reeling from a natural disaster of such a high magnitude, lengthy wait times aren’t a viable option.

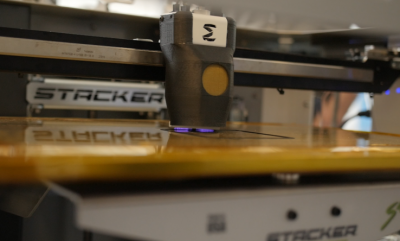

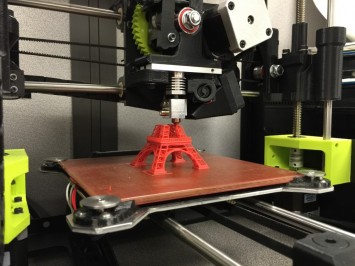

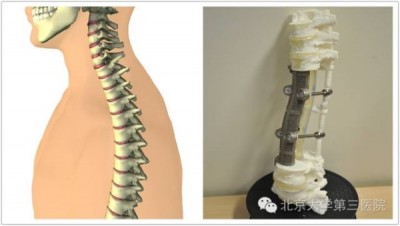

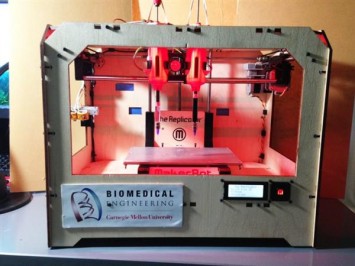

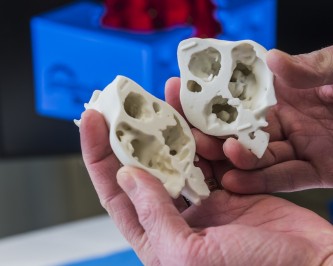

In response to the crisis, the US-based charity Field Ready has established itself in Bhotechaur. Yet while another American charity in South Asia isn’t exactly news, Field Ready offers something different: 3D printed medical resources.

Initially focusing on the design and manufacture of spare parts for machines damaged by the earthquake, Field Ready’s team of engineers soon realized they could help ease Nepal’s supply chain problem in another, more direct way.

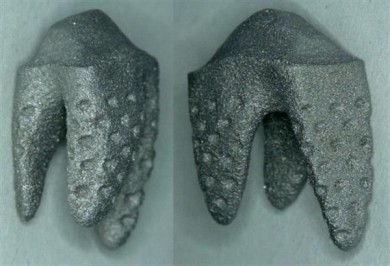

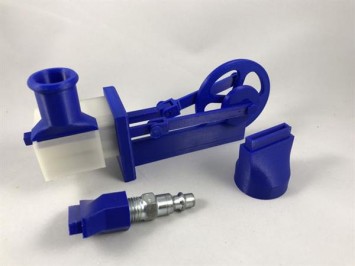

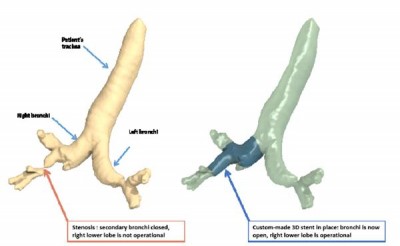

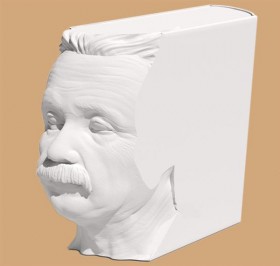

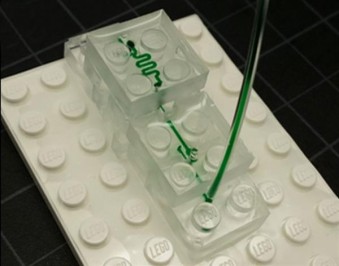

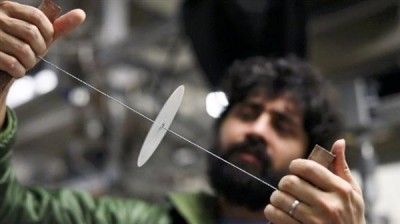

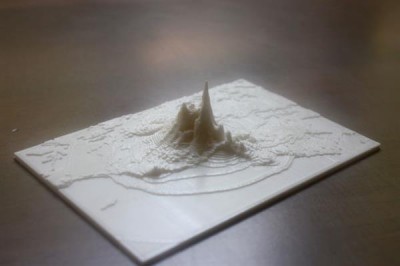

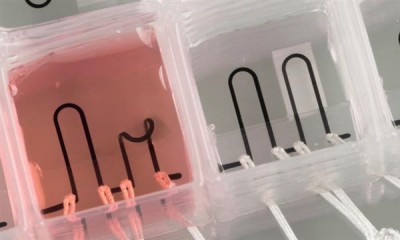

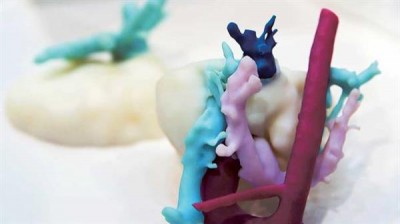

When Field Ready engineer Ram Chandra Thapa learned that doctors at a Bhotechaur clinic had no way to examine their patients’ ears for signs of infection, he designed and 3D printed a plastic otoscope.

a patient and her baby at a Bhotechaur clinic

“The items that we develop using 3D printers are cheaper, and they can be made in the field,” Thapa says. So far, doctors and medical practitioners are happy with the 3D printed equipment, he notes.

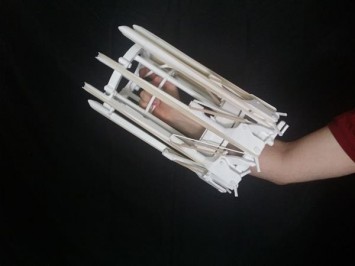

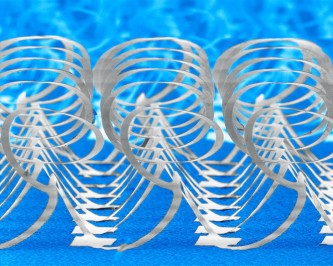

Thapa is currently testing designs for several 3D printed medical instruments such as plastic fetoscopes, tweezers, otoscopes, umbilical clamps, and wrist braces. Field tests are carried out at health clinics in earthquake-damaged villages like Bhotechaur.

“The instruments are very good,” says Bimala Upreti, a Bhotechaur-based nurse. “We are able to provide treatment for ear infections now when the patients come here.”

homes damanged by the 2015 earthquake

Patients, on the other hand, are impressed but say the clinics are still underresourced. The new equipment is good, they say, but there still remains no way to carry out important procedures like blood tests.

Thapa is now moving forward with designs for other plastic medical items. So far, those include kidney trays, forceps, sharp boxes, and stethoscopes. He hopes that 3D printers can eventually be permanently installed in remote health clinics in Nepal, where doctors and nurses could be trained, and then able to directly print their own supplies as needed.

Ideally, the project would be funded by charities, aid agencies, and the Nepal government, but as always, funding presents an obstacle.

“If they had 3D printers in their health clinics, they could just download 3D designs and print it there,” Thapa says.

For now, Field Ready continues to develop designs and carry out testing.

homes damaged by the earthquake