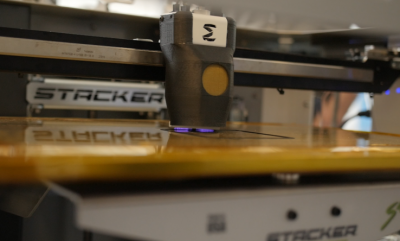

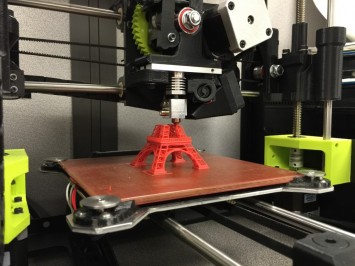

Stereolithography 3D printing specialist Formlabs has launched Durable Resin, the fourth 3D printing material in the Formlabs Engineering Resins range. The company says the 3D printing material is ideal for prototyping polypropylene parts.

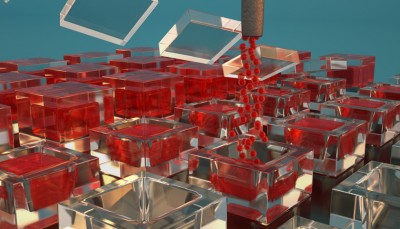

After bringing its new Ceramic Resin 3D printing material to CES 2017, Formlabs this week returned with another SLA 3D printing material, Durable Resin. The fourth item in the Formlabs collection of Engineering Resins (with Tough, Flexible, and High Temp), Durable Resin is Described by Formlabs as both stiff and flexible, and is recommended as a prototyping material for polypropylene parts. Since parts 3D printed with the resin have a have high impact strength and glossy appearance, the material is suited to fabricating prototype consumer products, packaging, and low-friction, low-wear moving parts.

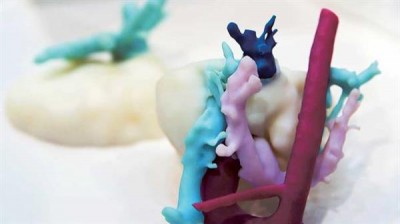

First formulated around 60 years ago, polypropylene (PP) is now used across the world for its low modulus and high impact resistance. It is commonly used in car bumpers, plastic chairs, and food containers, which—until recently—were almost exclusively manufactured using injection molding or CNC machining processes. Now, with Formlabs’ Durable Resin, companies and individuals can 3D print items that look, feel, and behave like polypropylene.

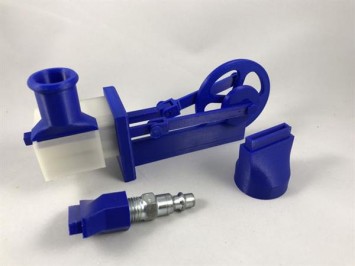

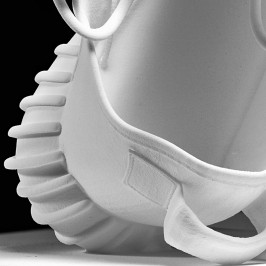

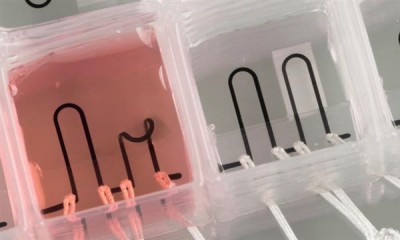

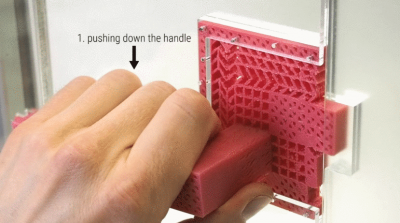

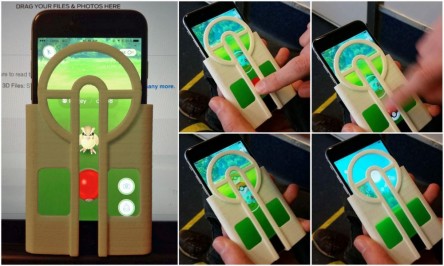

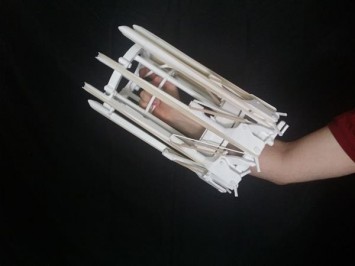

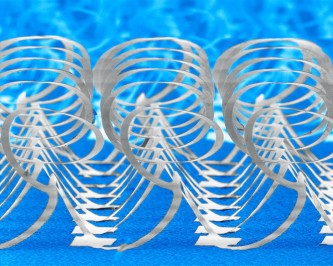

Formlabs recommends using its new Durable Resin for parts where deformation is preferred to breaking or cracking, or for parts that need to deform multiple times. Items like impact-resistant cases, snap fits, ball joints, flexures, vacuum-formed parts, and large assemblies that need to be disassembled and reassembled are all suitable for 3D printing in Durable Resin with a Formlabs SLA 3D printer.

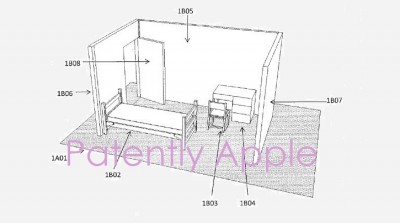

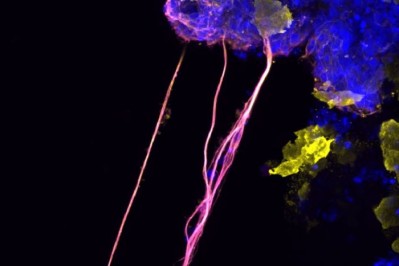

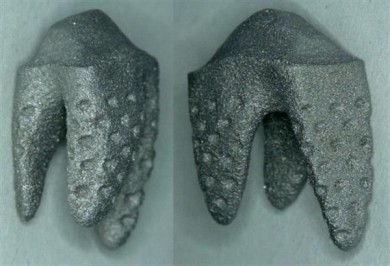

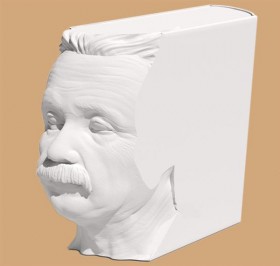

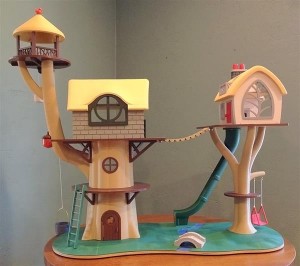

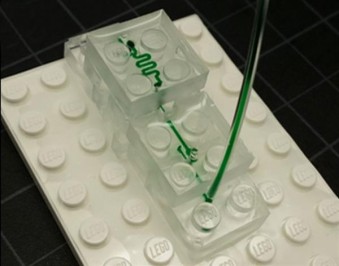

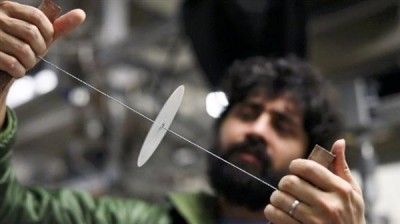

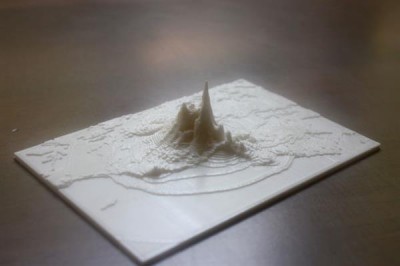

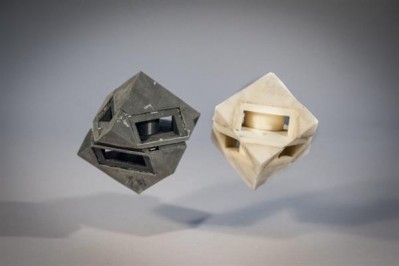

Items 3D printed with Durable Resin

When Formlabs gave us a first glimpse of Durable Resin back in October, it looked a bit different to how it looks today. Specifically, it was yellow. After consulting with consumers, however, Formlabs made a new formulation for its Durable Resin that produced a more versatile clear frosted appearance.

“When we’re developing new 3D printing materials to simulate existing plastics, we try to keep the focus on what qualities of that material the customer really cares about,” Formlabs explained. “To get a feel for this, we start by reaching out internally to Formlabs engineers Then, we talk to people using our printers outside of HQ to validate and determine what to focus on.”

After developing and testing the Durable Resin in larger quantities, Formlabs decided to change the formulation, a change which “improved the mechanical properties of the material, and removed the component that lent to the original yellow color.” Because of this decision, the Durable Resin 3D printing material is now translucent.

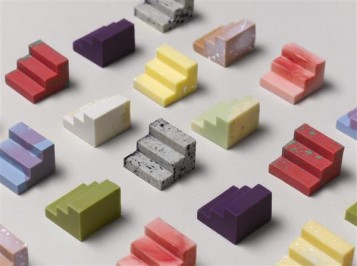

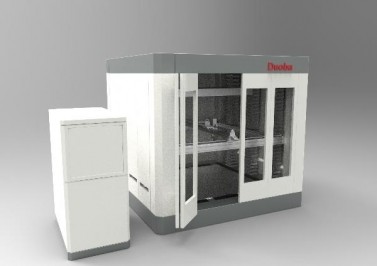

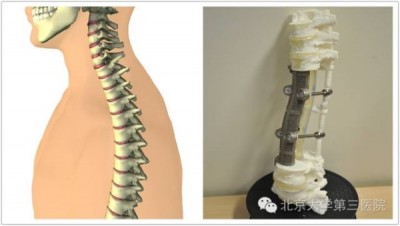

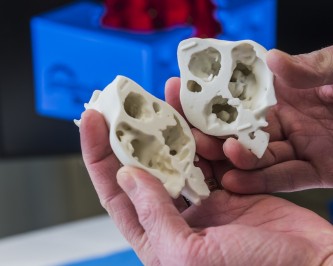

Durable Resin is the fourth addition to the Formlabs Engineering Resins collection

According to Formlabs, its new Durable Resin formulation is somewhere in between its Tough and Flexible resins. It costs $175 for a 1 L vat, the same as Formlabs Tough Resin but cheaper than Flexible and High Temp ($199 each). To use the resin, Form 2 users will have to update their software (PreForm and the Form 2 firmware).