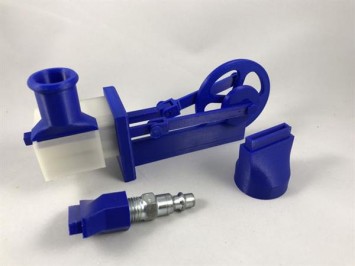

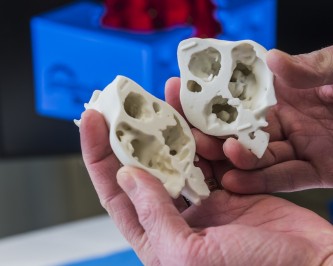

Online 3D printing service i.materialise has just announced that it has added a brand new 3D printing material to its already extensive selection: aluminum. The new material, which according to the company is ideal for manufacturing lightweight but strong metal end-use parts, is currently available through an official trial launched by the 3D printing service.

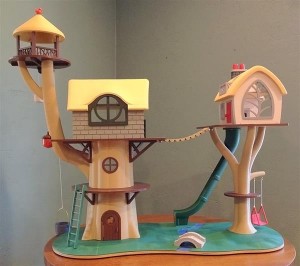

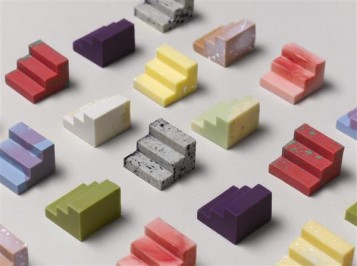

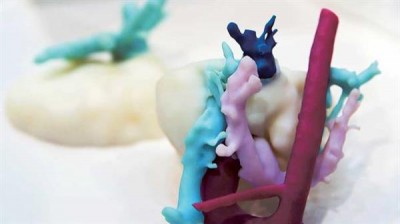

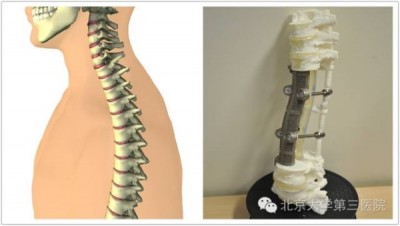

Aluminum, which is the most commonly used non-ferrous (or low-iron) metal, offers many benefits as a 3D printing metal material, most notably its light weight properties. i.materialise presents their new offer for aluminum 3D printing as a reliable way for designers, engineers, and makers to create strong, very lightweight, and precise metal parts. What’s more, the new material can be used for a wide variety of purposes such as manufacturing spare parts, functional parts, and design objects like jewelry.

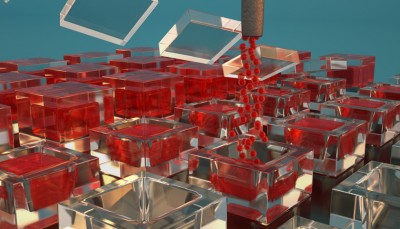

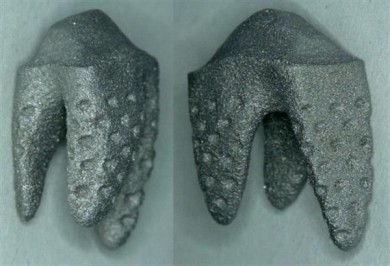

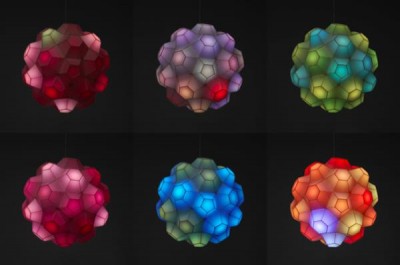

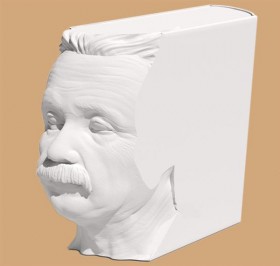

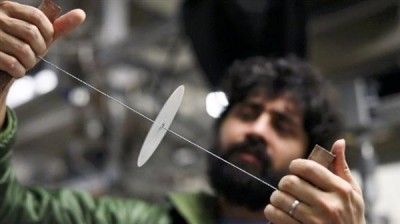

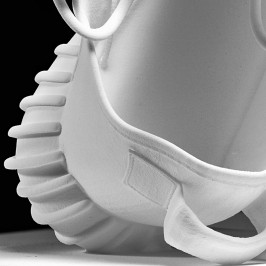

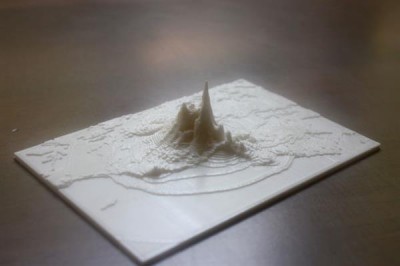

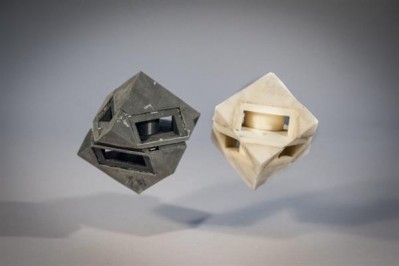

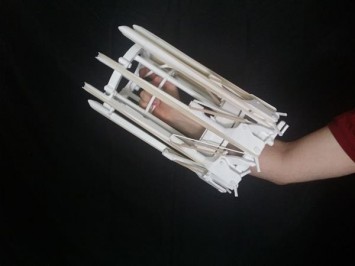

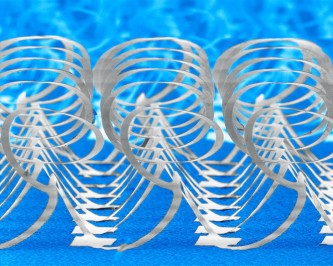

Unlike milled aluminum, which you’ll be familiar with from your everyday aluminum foil, 3D printed aluminum has a slightly duller finish. Rather than be bright and shiny, it offers a more subtle matte finish, with a slightly rougher texture as can be seen in the images above and below.

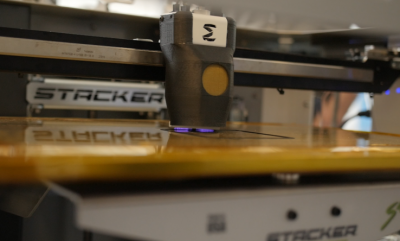

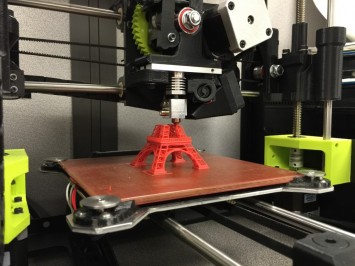

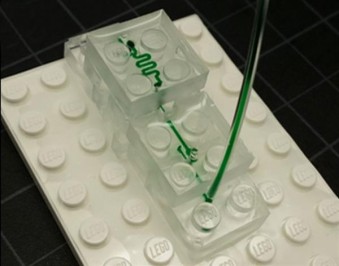

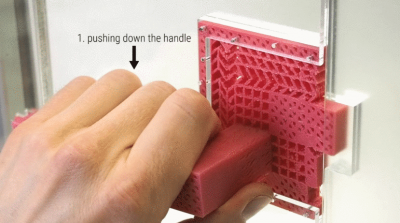

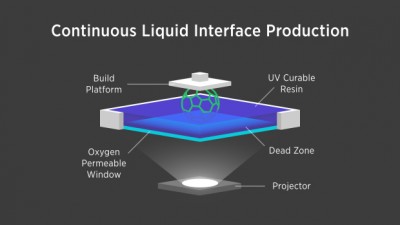

To 3D print with aluminum, i.materialise will be using the additive manufacturing method of direct metal laser sintering or DMLS, which consists of a laser beam and a fine metal powder, in this case an aluminum powder. In short, the laser beam sinters the metal powder in a particular shape (following your 3D model) layer by layer until your object is complete. When the laser sintering is done, i.materialise technicians can remove your model from the bed of metal powder and carefully remove any support structures and finish the piece.