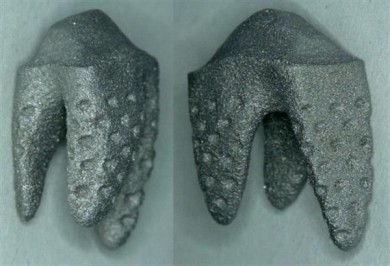

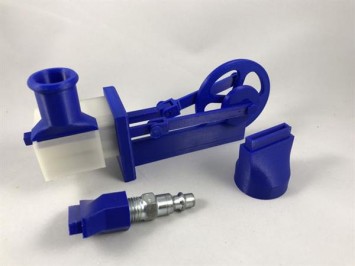

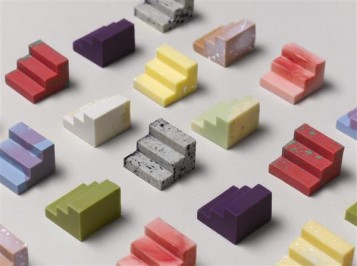

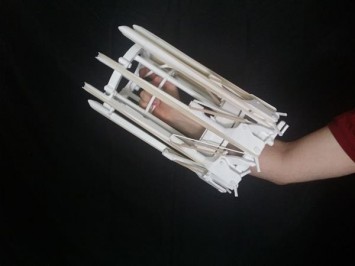

Australian bicycle accessory company Fetha Custom Components has introduced a 3D printed titanium mount for Garmin GPS trackers. Each mount is made to order depending on a customer’s Garmin unit and stem setup.

With GPS technology now more advanced and affordable than ever, the days of seeing disheveled cyclists struggling with giant roadmaps are almost over. Tracking devices such as those made by American tech company Garmin can now be used to map routes, measure journey times, and much more. But despite the incredible usefulness of such technology, some riders are unable to use Garmin’s out-front or quarter-turn bike mounts; others use Garmin units which aren’t built specifically for bike use. For these cyclists, a custom solution is required. Step forward Fetha Custom Components, a Melbourne-based accessory maker which has introduced a range of made-to-order Garmin mounts for bikes.

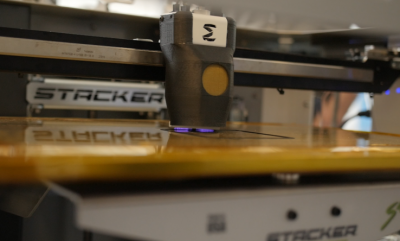

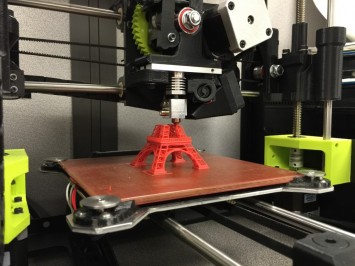

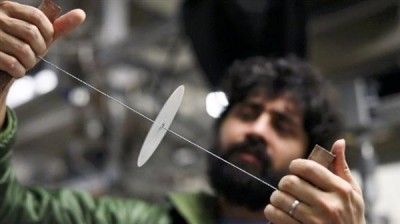

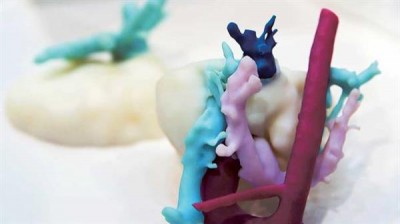

Founded in 2011, Fetha is run by Zimbabwe-born engineer Jamie Riedy, who has been creating custom parts and accessories for a number of years. The cycling enthusiast started off by building custom seat toppers using a CNC mill, and has since expanded to other products and manufacturing methods, including 3D printing. Fetha’s latest product, made with the help of students and staff at Melbourne’s RMIT University, is a 3D printed titanium Garmin mount, available in different styles to suit any combination of handlebars, frame, and Garmin unit.

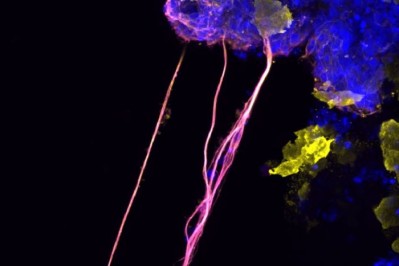

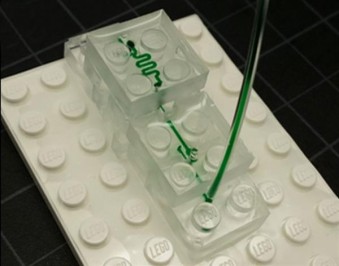

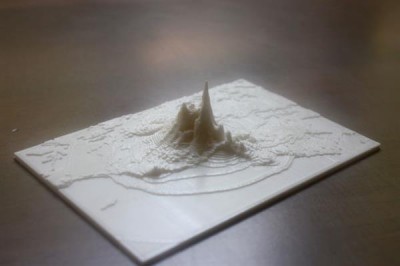

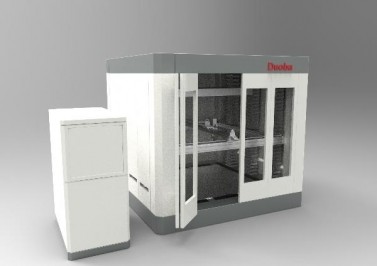

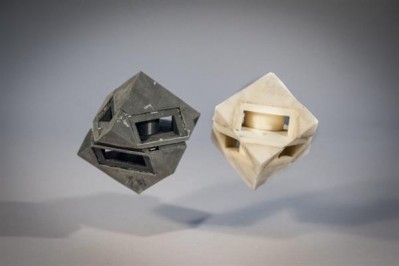

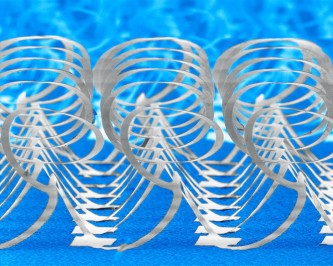

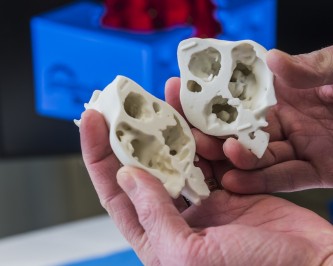

Riedy and RMIT have been using an SLM Solutions 125HL 3D printer, which has a build envelope of 125 x 125 x 125 mm³, to create the 14g titanium parts. In order to save on material and power costs, several units can be merged into a single CAD file and printed in one go, after which all support structures can be carefully removed. Once this process is finished, each 3D printed mount is packed with a set of titanium screws and shipped off to its corresponding customer.

Fetha is confident that its 3D printed bike mount offers riders a unique solution currently unavailable from any other provider: “With a large number of bike brands heading towards aero handlebars (integrated and non-integrated) it has made it difficult to attach traditional mounts to the bars,” Riedy told Cycling Tips. “Not only this but all brands seem to differ slightly in terms of bolt pitching or position. This is where Fetha fills a niche, customizing components to suit these products.”

Fetha is able to build a customized 3D printed mount in about 3-4 weeks, and each product comes with a full three-year warranty. The mounts cost AU$140 (106 USD) apiece, shipping included.