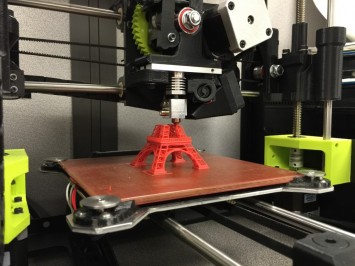

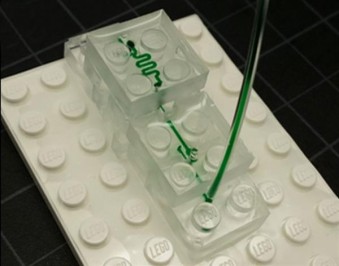

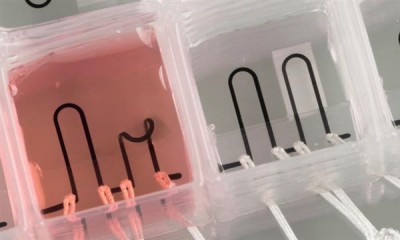

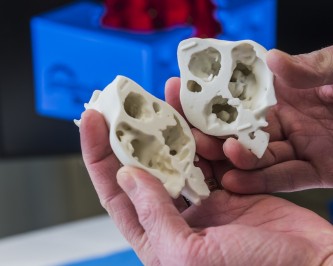

The use of 3D printed LEGO bricks is something that we have reported on before, and now this appealing combination of a childhood toy with cutting-edge technology has appeared again, but with an innovative practical use. Biomedical researchers in California have developed a modular microfluidics system that is built up of classic 2x2 LEGO blocks, each of which have been made with a 3D printed mold that allows for the integration of customized fluid channels.

Microfluidics is a technology based on the idea that a moving fluid, when confined, will behave in a way that is similar to a stream of electrical current, as modelled by the binary logical operations that are familiar from the domain of electronics. It works by the manipulation of fluid at the microscale, using pressure regulators or syringe pumps to set it in motion along set paths, and scientists and engineers have recently seen the potential for its use in biomedical applications.

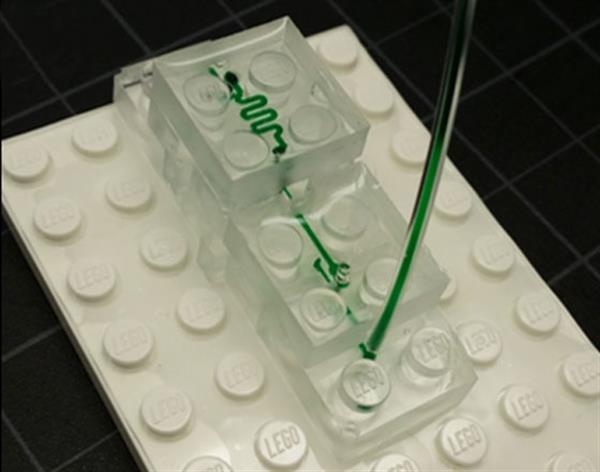

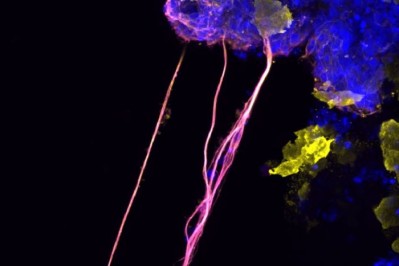

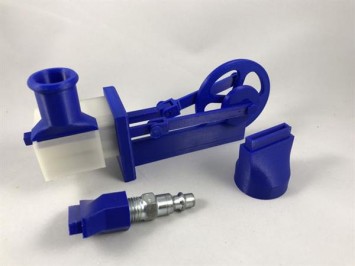

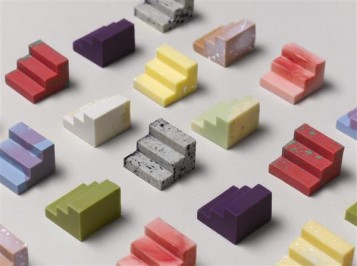

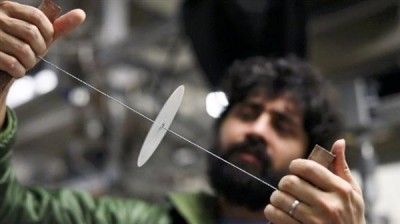

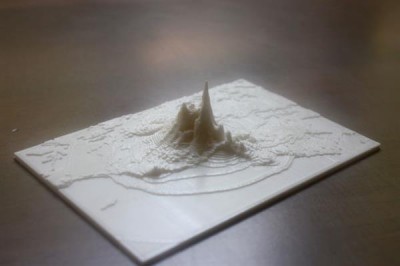

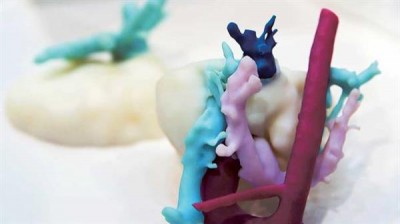

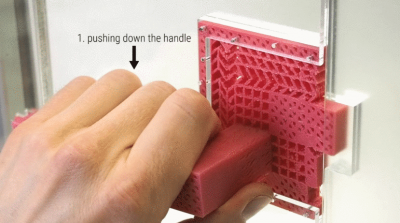

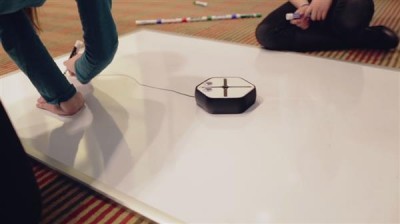

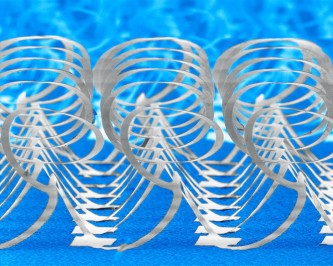

A single microfluidic basket weave with 2 layers of blocks. No leakages are visible.

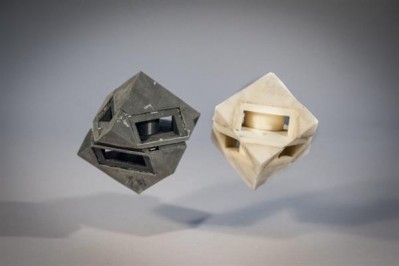

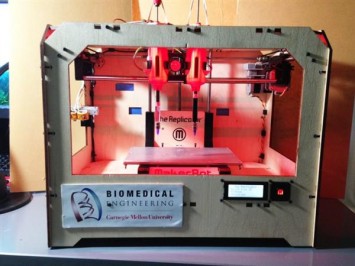

The results of this new research were published in the Journal of Micromechanics and Microengineering (JMM) by a team from the Department of Biomedical Engineering at the University of California. One member of the team, Kevin Vittarayarukskul, describes a typical microfluidic device as being like a piping network, ‘‘except the pipes have diameters in the submilimeter range.’’ Although 3D printing has been used in the past to make these devices, using it simply to make the mold for the blocks which can then be easily assembled together in a variety of different structures is a much more straightforward and cost-effective solution. According to Vittarayarskul, ‘‘Like traditional LEGO bricks, they are stackable, and their geometry makes mass production by precision moulding feasible.’’

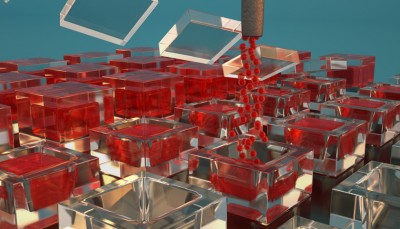

As another researcher, Professor Abraham Lee, states: ‘‘microfluidics remains a relatively niche area because of the difficulties in fabrication and assembly.’’ He hopes that this intuitive LEGO-based system ‘‘will encourage a broader range of researchers to adopt the technology and explore the possibilities it offers.’’ The team hopes that this new development will allow non-experts of all ages to get involved with microfluidics, and microengineering generally. They intend to produce a "library" of basic blocks from which highly elaborate and complex structures can be created—even by those with little to no prior knowledge of the physics behind their designs.

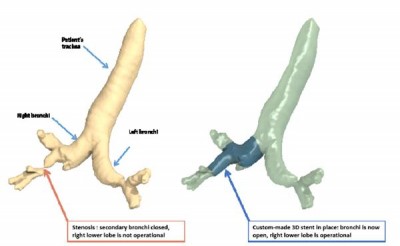

The range of applications possible for microfluidics is vast, and some of them will have a crucial effect on healthcare and society in general. According to Lee, ‘‘these include point-of-care diagnostics; 'smart' nanomedicine for early detection and treatment; tissue engineering and stem cells; and biosensors to detect environmental and terrorism threats.’’ The medical uses are particularly promising due to the miniaturisation of the system, which allows for smaller devices and sample requirements.

With the aid of 3D printing, and thanks in no small part to the enduring appeal of LEGO bricks, this new breakthrough means that the next generation of bioengineers may already be in training as we speak.