In an effort to bring local and sustainable manufacturing back into the toy making industry, one father-son team has founded Luke’s Toy Factory. Based in Danbury, Connecticut, the new toy brand is putting a new spin on classic toys, and is doing so using entirely U.S. based resources. So far, the company has released 4 toy truck models, each made from plastic wood composites, which it has developed with the help of 3D printing.

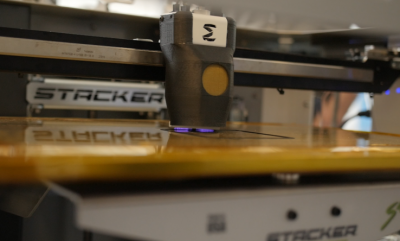

Founded by father and son Jim and Luke Barber, Luke’s Toy Factory is hoping to re-introduce some good old American manufacturing to the growing consumer toy market. Jim, who was inspired to make his own toys when he learnt about wood-plastic composites some years ago, partnered with his son, who created the first prototypes for the toy trucks using 3D modeling and 3D printing.

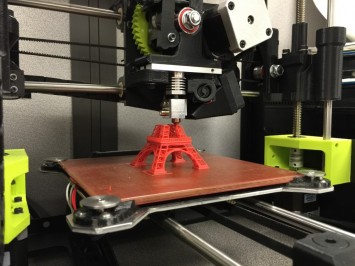

The pair launched a Kickstarter campaign for their innovative toys and raised $15,000 to get their products off the ground. Importantly, the crowdfunding campaign also connected them with Southington, Connecticut-based Vanguard Plastics Corp., which is helping them with manufacturing. Of course, 3D printing had a big part to play in the prototyping stage for the trucks.

“If not for 3D print testing we would spend thousands of dollars to get a mock up, only to discover in many cases that it didn’t work,” Luke explained. “With 3D printing we spend about $50 to make a prototype part. We wouldn’t be able to do it without 3D printing.”

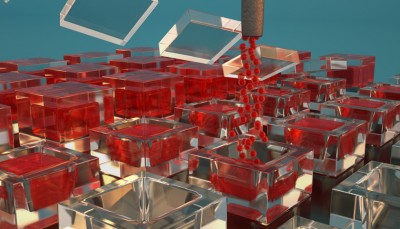

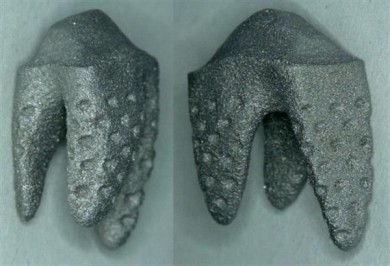

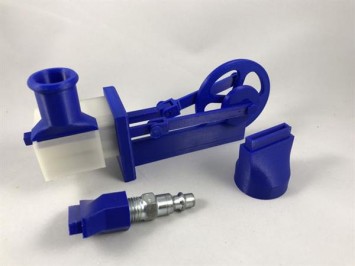

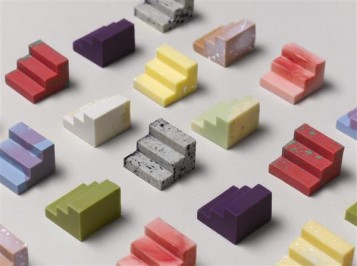

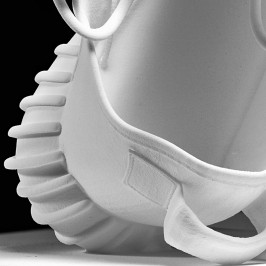

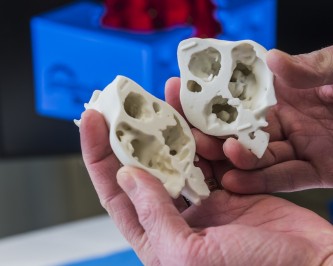

After having designed and vigorously tested their 3D printed toy truck prototypes, Luke’s Toy Factory has rolled out their first line of toys. Though the final products are not 3D printed, they are made from a wood-plastic composite material that is made from maple-wood sawdust from a U.S. furniture factory. According to the company, the sawdust makes up 30% of the toy’s material, and just a small amount of colored dye has been added to the material, which eliminates the need for paints.

The toy trucks, which are made up of seven separate parts, are manufactured by Vanguard using single and multi-cavity molds which are used in a 50-ton Boy injection press. Once the toys parts are made, the trucks are assembled, packaged, and shipped out by the workers at Luke’s Toy Factory. Jim Barber estimates at least 40 people are involved in realizing the toys.

wood pellets used for making the trucks

He says, “There are at least 40 people involved with making this toy. There are so many facets to it. It’s not just the four of us here in Danbury. And everyone involved gets paid a living wage. One of the reasons we are doing this is to show it can still be done. With manufacturing, there is a multiplier effect. Whole groups of people are affected by where you are.”

The trucks, for those interested in purchasing them, are currently stocked in about 225 specialty toy stores and gift shops around the U.S. Made for ages three and up, the trucks can be disassembled and put back together easily, meaning that parts from the different models are swappable. They are retailing for about $23.