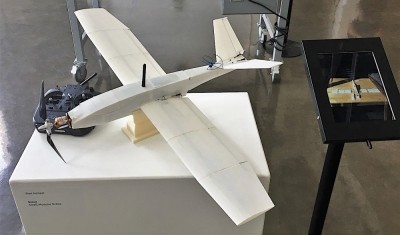

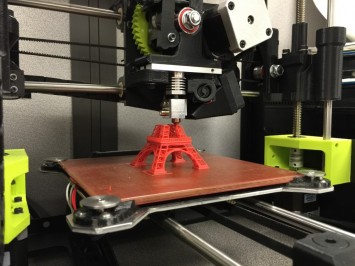

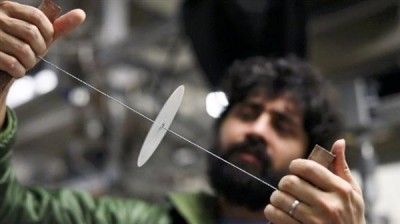

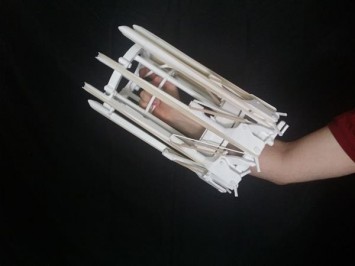

The ILA Berlin Air Show 2016 which took place last week has been generating a lot of buzz and excitement, most notably for Airbus’ innovative mini-plane Thor, an almost entirely 3D printed unmanned aircraft. The 3D printed windowless plane, which weighs just 46 pounds (21kg) and measures less than 13 feet (4 meters) in length, was much smaller than most of the other aircraft being showcased at the Air Show, though as we have seen, was no less exciting.

According to European aerospace company Airbus, who is responsible for developing Thor (which is short for Test of High-tech Objectives in Reality), the 3D printed aircraft marks an exciting turn in the aircraft manufacturing industry. That is, Thor marks a pioneering step in the integration of 3D printing technologies in the aerospace industry, a step which could result in a higher level of time, cost, and fuel efficiency.

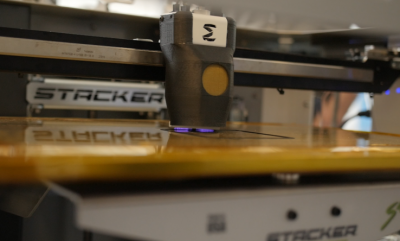

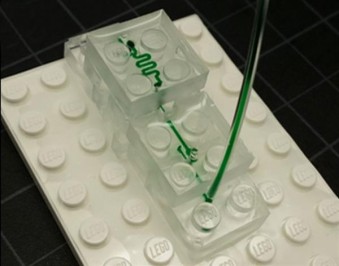

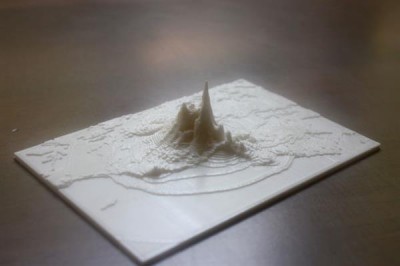

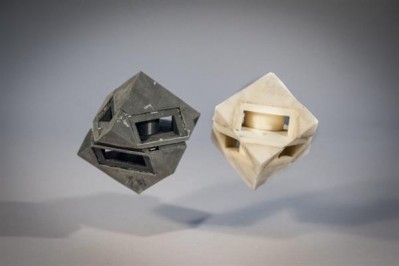

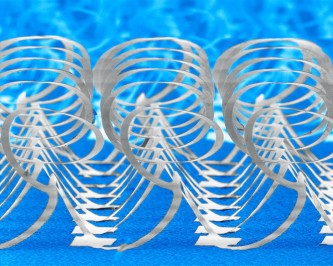

Thor, a first generation prototype, was successfully flown last November near Hamburg, Germany, though it was not flown at ILA Berlin. As mentioned, the entire aircraft, save for its electrical components, was additively manufactured from a polyamide material.

“This is a test of what’s possible with 3D printing technology,” said Detlev Konigorski, the project head for developing Thor, at ILA Berlin. “We want to see if we can speed up the development process by using 3D printing not just for individual parts but for an entire system.”

The little plane "flies beautifully, it is very stable," said its chief engineer Gunnar Haase, who conducted Thor's inaugural flight last November.

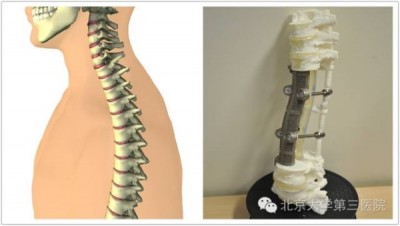

As we well know, players within the aerospace industry, like Airbus, have been using 3D printing technology for years to develop prototypes and specially made replacement parts and components.

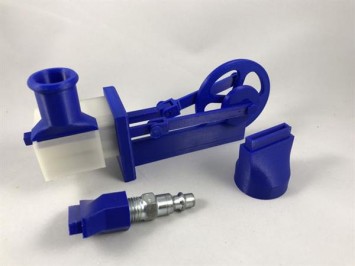

"The printed pieces have the advantage of requiring no tools and that they can be made very quickly," said Jens Henzler of Bavaria-based Hofmann Innovation Group, which specialises in the new technology.

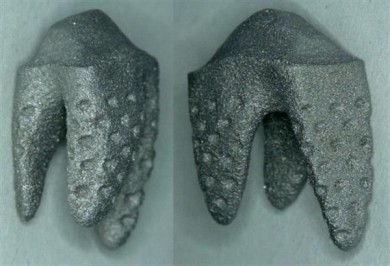

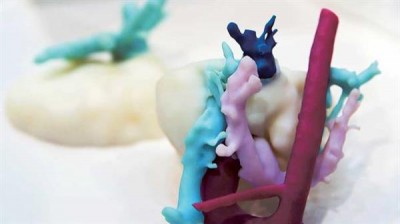

The metal parts produced can also be 30-50 percent lighter than in the past, and there is almost zero manufacturing waste, added Henzler, who is managing director for Hofmann industrial prototyping.

The Airbus innovators also revealed that the technology has proven to be an excellent weight-saving solution. 3D printing thin layers of power material has enabled them to optimize part designs and minimize material use. And as weight is the most important cost factor in aviation, this could be a crucial innovation. "It brings big cost reductions on parts manufacturing," said Alain Charmeau, head of Airbus Safran Launchers.

Aside from the costs savings, 3D printing also promises ecological benefits as lighter jets use less fuel and spew out fewer pollutants.

To reducing carbon emissions in aviation—with air traffic expected to double in the next 20 years—"the decisive issue is radical technical innovation in a relatively short time," said Ralf Fuecks, head of the Heinrich Boell foundation think tank of the German Green Party.

3D printing is certain to play a major role in this, he said at a conference at the ILA event with Airbus president Tom Enders.

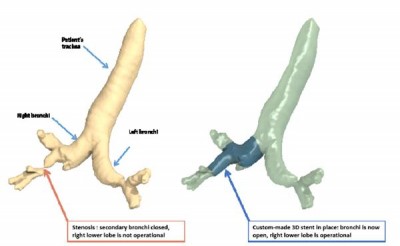

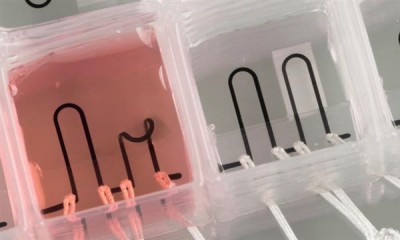

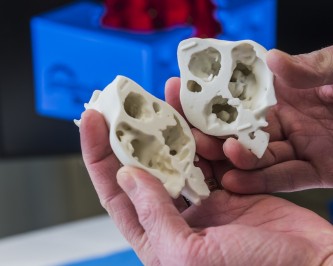

Charmeau said Airbus is testing how to print an injection assembly for an engine that is now assembled from 270 individual pieces.

"With 3D printing, it has just three parts," he told AFP.

Thor marks a significant moment in the advancement of additive manufacturing technologies within the industry and continues to emphasize the viability and benefits of 3D printing.