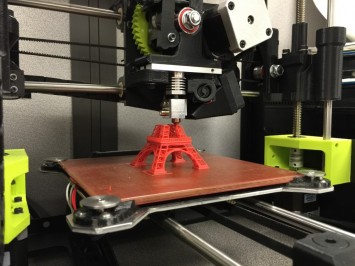

"The people closest to the problem are also the people closest to the solution," Capt. Chris Wood, co-lead for Additive Manufacturing with the US Marine Corps, told Engadget. In 2016, the USMC put that adage to the test as it launched the Logistics Innovation Challenge, a program "to solicit ideas from Marines, sailors and civilians from across the Marine Corps" that would address challenges that they face in their daily duties. And this is only the start to the US Military's additive-manufacturing aspirations. Pretty soon, everything from ammunition to autonomous vehicles could come from the Corps' cadre of 3D printers.

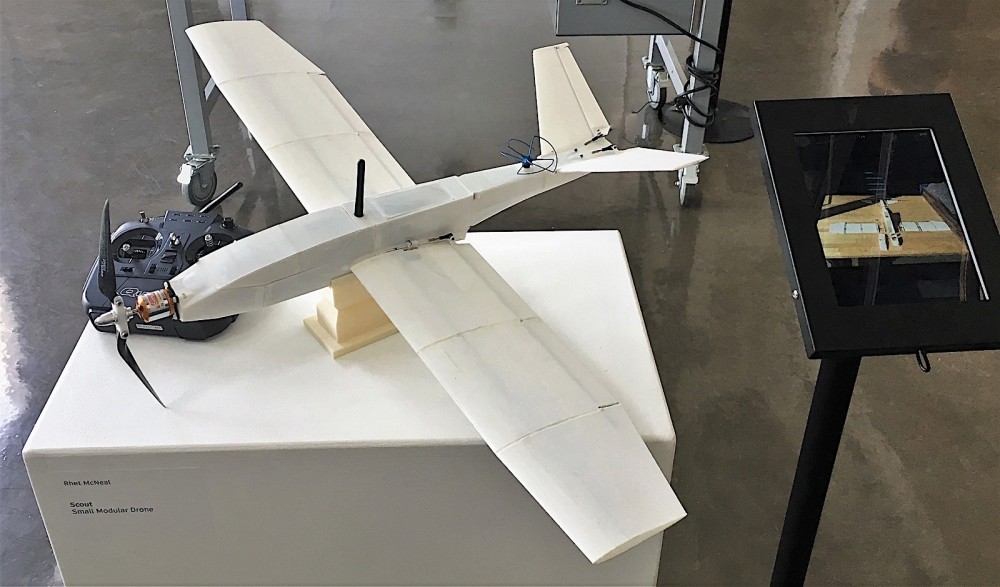

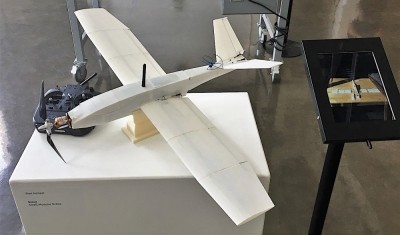

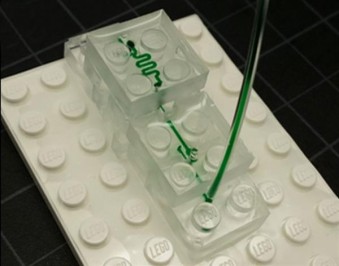

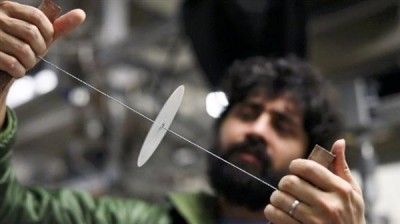

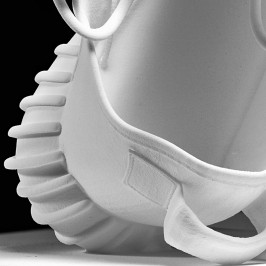

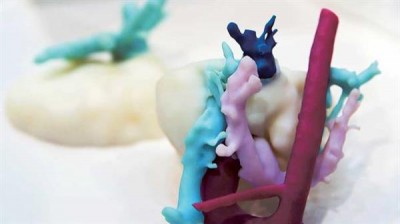

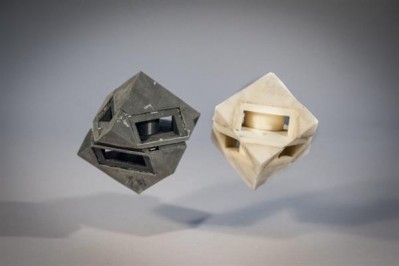

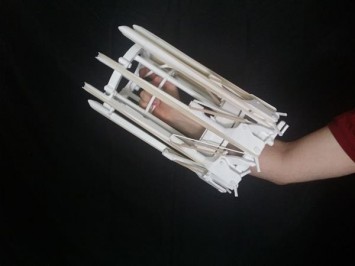

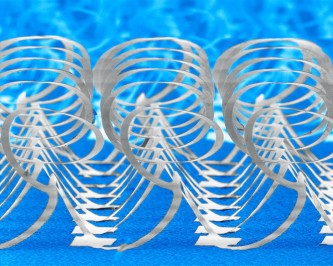

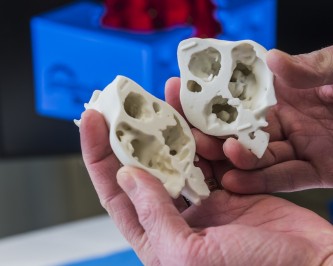

Of the hundreds of submissions, only a handful managed to make the final cut and enter prototype development. Among them, 26-year-old Corp. Rhet McNeal's Scout, a fixed-wing UAS (unmanned aerial system) constructed almost entirely from 3D-printed components. Conventional Intelligence Surveillance and Reconnaissance (ISR) drones can cost hundreds of thousands of dollars to construct and operate, making commanders more reticent to use these devices in the field out of fear of breaking them.

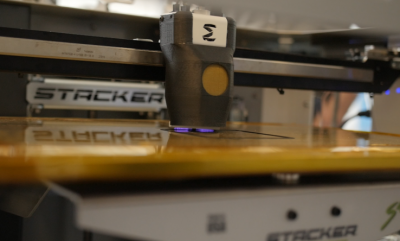

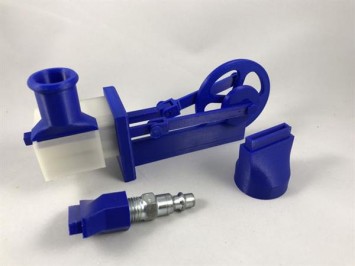

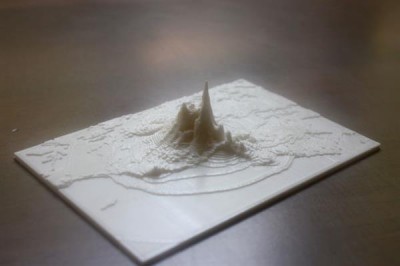

Scout, on the other hand, costs only around $600 to build. It also fits in a standard-issue pack, can be broken down in a little over two minutes, and assembled and in the air within five minutes, McNeal told Engadget. And because its body and wings are 3D-printed, if the drone does take damage, troops can print a replacement part in a couple hours using in-field 3D printers rather than waiting days, weeks or even months for replacements to worm their way through the Marine Corps' supply lines.

"I don't see this as replacing our current supply chains, but I do see it as a great opportunity to augment existing capabilities," Lt. Col. Gregory Pace, battalion commander of the Marines 1st Maintenance Battalion, told the Marine Corps Times last year.