Grant Cowie, an engineer and pre-war motorcar specialist from Australia, has used 3D printing to restore a 103-year-old grand prix car. The vehicle, whose engine was recreated using a 3D printed sand mold, is the only surviving 1914 Delage Type-S in the world.

Restoring a battered-up old vehicle can be difficult. But restoring a 103-year-old car with no spare parts, no drawings, and no assistance from the manufacturer is nigh-on impossible—unless you happen to be one of the best in the business. For Melbourne-based engineer Grant Cowie, rebuilding the 16-valve engine of the world’s only extant 1914 Delage Type-S presented a giant challenge, but—with the help of 3D printing—he was ready to tackle it.

Delage was a French luxury car manufacturer based near Paris. It was founded in 1905 by Louis Delage, and built vehicles for almost 50 years, ceasing operations finally in 1953. With the last remnants of the company’s manufacturing facilities now long gone, it is increasingly difficult to find a Delage vehicle, let alone one in working order.

For many years, car lover Stuart Murdoch had driven and maintained the world’s only 1914 Delage Type-S, making small repairs where necessary and generally treating the antique vehicle with the respect and adoration it deserves. But in 2014, disaster struck: while Murdoch was driving, the Delage’s engine block cracked; water met oil, and the car ground to a halt. The pre-war vehicle was brought to a mechanic, but there were fears that the Type-S might have made its last journey.

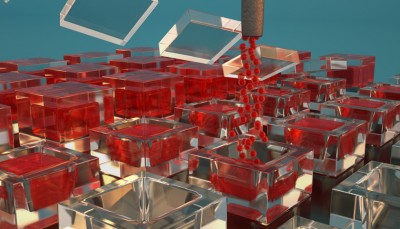

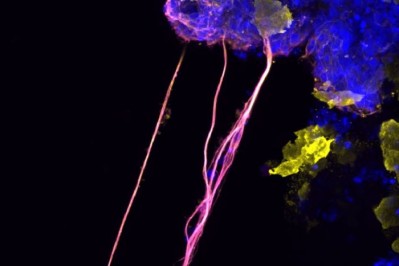

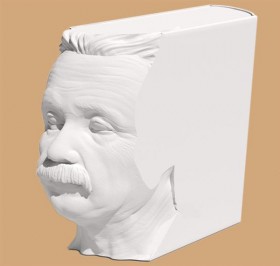

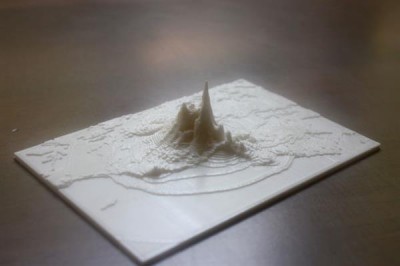

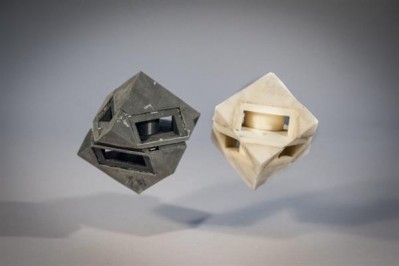

3D scanning and 3D printing were used to restore the Delage engine

Fortunately, pre-war motorcar expert Cowie, who received the busted auto soon after its breakdown, was ready to do anything to keep the car running. “I knew that to use the traditional method, which involves a wooden pattern, would be prohibitively expensive and with such a complicated casting it was possible it would take several attempts to get it correct,” Cowie told ABC.

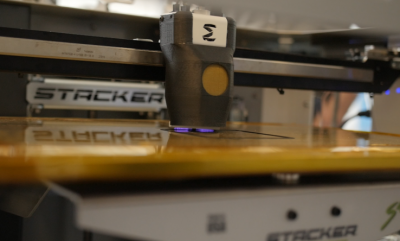

Rejecting the pattern method on the grounds of both cost and time, Cowie instead decided that 3D printing and 3D scanning technology could be used to rebuild the engine in the most effective way. There was, however, one small hitch: no mechanic had ever attempted this kind of digital reconstruction on such a complex problem on such an old car.

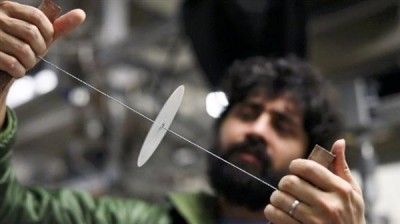

Grant Cowie (above) and the dash of the 1914 Delage Type-S

(Images: ABC Radio Melbourne / Fiona Pepper)

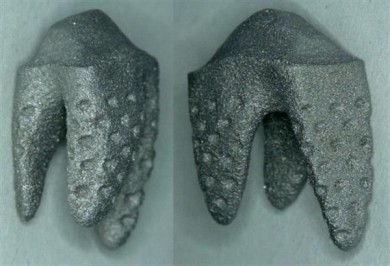

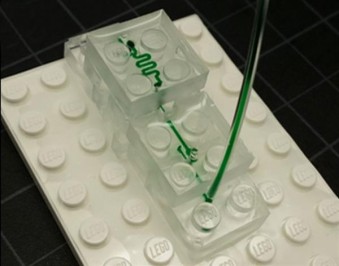

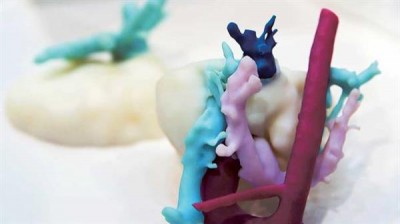

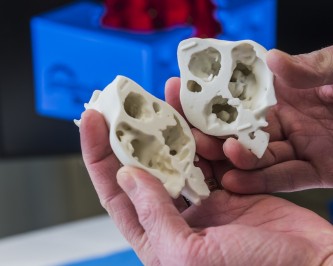

Cowie pressed ahead nonetheless, determined to get the Type-S back on the road for owner Murdoch—and for car lovers everywhere. First came the 3D scanning: over the course of a few days, Cowie used laser scanners to scan the engine block inside and out. Had he opted for pattern making, these days would have turned to weeks or even months.

When this 3D scanning data was loaded up onto a computer, Cowie was able to clearly spot the cracks that had caused the car to fail. Using his CAD skills, the engineer fixed these cracks on-screen. Now he just had to turn that faultless digital model into a real engine.

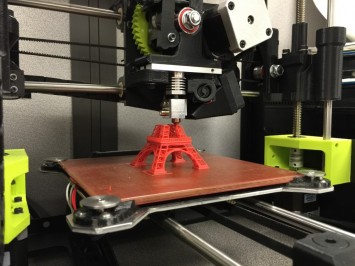

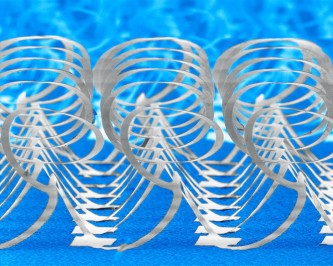

Using a 3D printer, the Australian engineer created a sand mold for the engine, which was then taken to a local iron foundry where a new version of the engine was cast in the 3D printed mold. This new iron engine was then finished using traditional machining tools.

Restoring the 1914 Delage Type-S

Using 3D scanning, 3D printing, and established manufacturing tools, Cowie had created a new engine for the pre-war Delage Type-S. But the most important stage was yet to come: before anyone could celebrate, the engine would have to be tested in the vehicle.

Fortunately for all concerned, the Type-S started successfully, and Murdoch was able to drive the priceless auto away. The cast-iron engine, made with the help of 3D printing, will hopefully keep the vintage vehicle on the road for many more years.

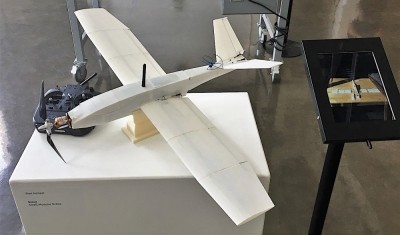

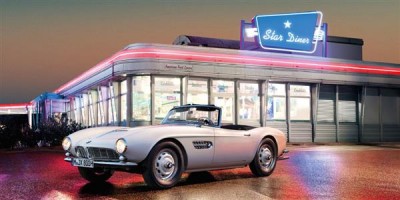

A 1914 Delage Type-S in its heyday

(Images: Philip Guilfoyle)

“It is a considerable achievement for all those involved and, might I say, quite an achievement for Australian engineering,” said a relieved Murdoch.

Philip Guilfoyle, project manager for the restoration, thinks that the success of the project could prompt other mechanics to be more open to digital manufacturing techniques like 3D printing. If it keeps more cars like the Type-S on the road, we hope he’s right.