It’s the same in almost any sport: while the equipment does the job, its rarely comfortable. From clunky pads to badly fitting mouth pieces and grips that provide no support: they’re often far from ideal. Fortunately, as evidenced by Under Armour's customizable 3D printed soles for sports shoes, 3D printing is playing an important role in customizing wearable equipment to better protect the user and provide more comfort. In the case of snowboarding, Australian student and entrepreneur Robert Leen has even said that 3D printing has the potential to not just make snowboarding more comfortable, but even to improve performances.

Leen, a master's student studying engineering at Deakin University in Australia, can regularly be found on the slopes strapped onto a snowboard. But, like most snowboarders out there, restrictive boot bindings are his bane. While a beginner user will be more comfortable staying relatively upright for the whole downhill trip, experienced users seek more control and responsiveness while they cruise down the hill.

This level of responsiveness is difficult to achieve with bindings that completely encase your foot and ankle, and unfortunately snowboard binding technology has stayed the same for decades. As a result, snowboarders are often forced to over-tighten the bindings, crushing their toes to gain just a little more control over the downhill process. It is also a prime source of frustration, with 32 percent of snowboarders arguing that this is a significant problem for them. As we're learning, however, 3D printing could provide an answer. “Because snowboarding technology hasn’t changed much over the past 20 or 30 years, we were able to look at the new 3D technology available today and create something that wasn’t possible in the past,” Leen reveals.

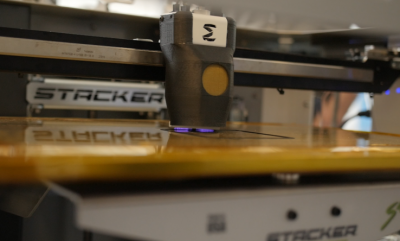

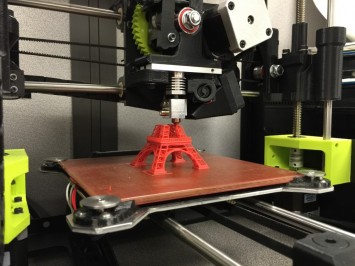

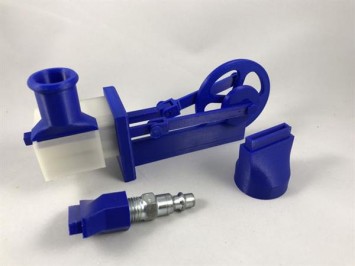

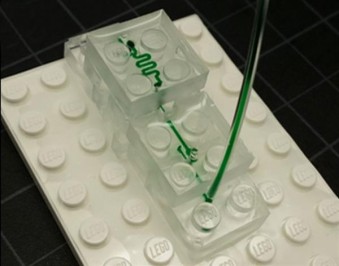

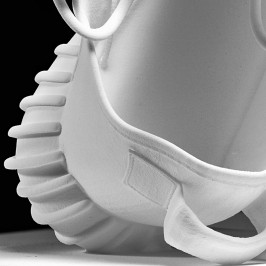

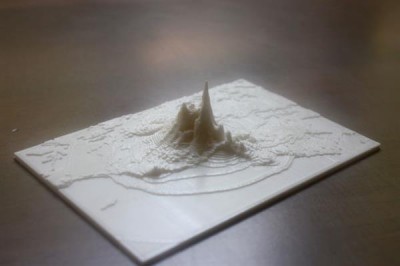

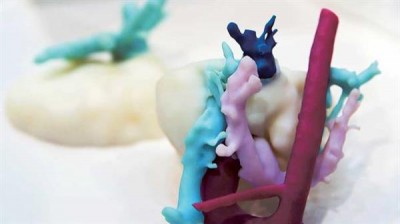

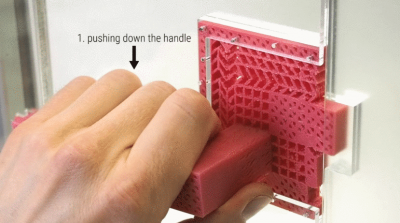

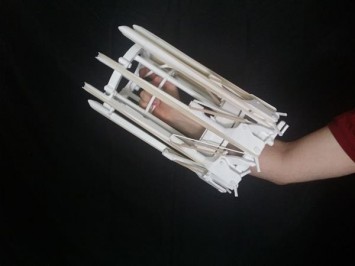

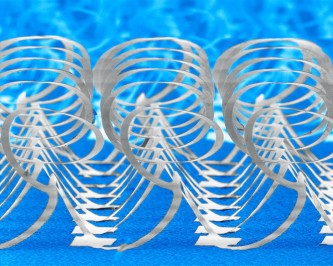

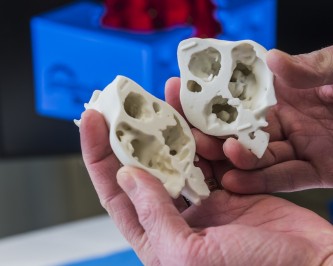

The solution? The Griptight Snowboard Binding, an invention Leen prototyped with supervision from Deakin’s Dr. Paul Collins and Dr. Clara Alvarez. “A feature of the Master of Engineering is its emphasis on functional prototyping, which is central to the design process,” Dr. Collins says of the project. In a nutshell, this 3D printed concept replaced the reel and steel lace of a typical snowboard boot with a much more flexible alternative, giving snowboarders more control, comfort and flexibility in binding.

During Griptight Snowboard Binding's development, Leen 3D printed a prototype and tested it himself on a number of runs. His design relies on the patented BOA system, a closure method often used by mountain climbers. In this iteration, it consists of a reel and steel lace cable system placed in the body of the boot. Leen further pulled the boot back and made its sole a structural, rigid part. This eliminates the risk of overtightening, while giving the wearer a much greater level of control.

It’s a concept that has already received critical acclaim from experts and even won Leen a finalist position in the Young Australian Design Awards. “Becoming a finalist was a great honor and experience in putting myself forward,” he says. “It has encouraged me to keep developing my skills in design and product development for the future.”

So what’s next? Well, Leen has become even more convinced that 3D printing can revolutionize snowboarding, and is currently working to set up a winter sports apparel company that pioneers more 3D printed custom solutions. “I am currently looking at design methodologies within sports technology, particularly collaboration between academia and industry,”Leen says. “There is a strong need to improve knowledge within industry of the capabilities of new technology and the types of products that could be developed.”