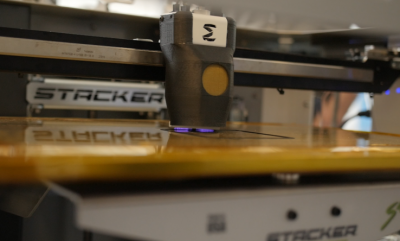

Leading toy manufacturer Fisher Price has been taking advantage of 3D printing technology, using it to rapidly prototype its new product ideas so they can be tested hands-on by designers looking for faults to be corrected or improvements to be made. The company is now also making use of innovative virtual reality techniques, in creating the soon-to-be-released BatBot Xtreme, the flagship toy for its new 2017 line.

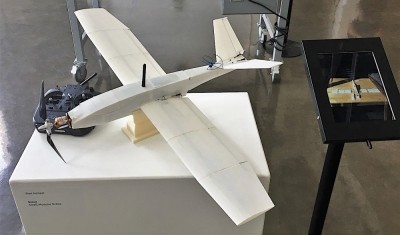

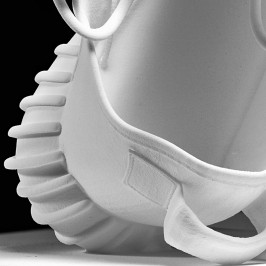

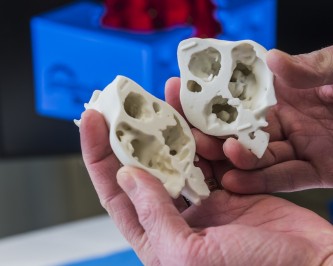

One of the most important aspects of the design process for a new toy is the practical testing phase, when the product is put through various trials by designers attempting to replicate the experience a small child might have with it. They must check to see if the toy is safe, if it will break easily, if any mechanical elements are functioning as they should be and, most importantly, if it is fun to play with. For Fisher Price’s latest development, the BatBot Xtreme, a Batman-themed robot toy, initial feedback was very positive except for one thing- the six-inch figure was too small. Before the larger version was ready for the manufacturing phase, it would also have to be tested, to see what difference the size change would make to the user experience.

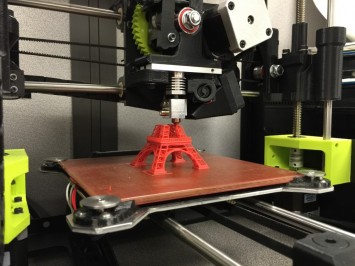

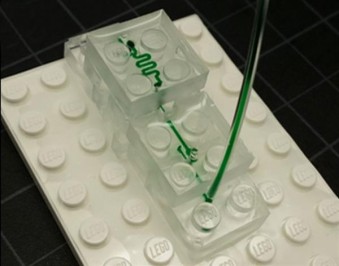

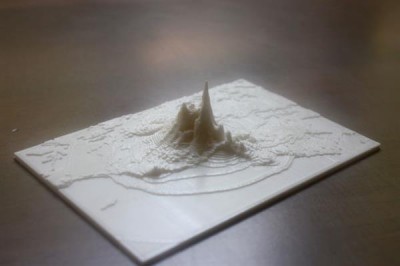

This is where 3D printing technology often steps in. Working from a virtual 3D model of a product means that it is straightforward for Fisher Price’s designers to scale their projects up or down. The CAD files for a newly proportioned version of a toy can then be sent to a 3D printer, for a quick prototype to be built and put through its paces before large-scale manufacturing begins. However, with the BatBot Xtreme project, even the short 7 day period required to build a test model with 3D printing techniques wasn’t fast enough. The flagship product for Fisher Price’s 2017 Imaginext line of action toys was withdrawn at the last minute, so the company was without a new awe-inspiring product to grab kid’s attention. The pressure was now on for Batbot’s design team to finalise their project and get it on the market.

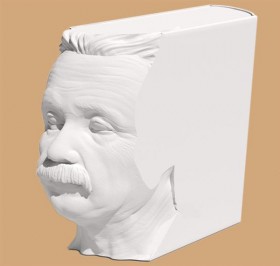

“When you get that physical toy from the screen for the first time, there’s a state change. We need to get across that barrier as quickly as possible,” said Tyler Berkheiser, design director of the Imaginext brand. “We quickly realized we don’t have time to build this model. How could we realize if this works?” The groundbreaking solution that the team arrived at was not to build a prototype at all, but to allow their designers to interact with the 3D model in a virtual environment.

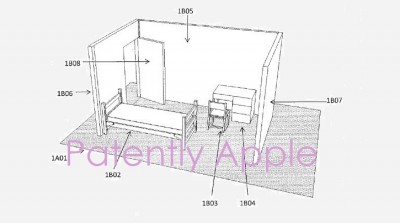

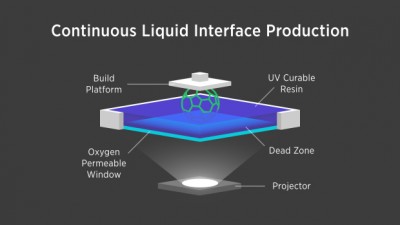

John Krisman, the R&D technical lead at Fisher-Price, had been experimenting with VR and AR (augmented reality) technology in the creation of animated content to promote the company’s various products, and he had also seen its potential to be used in the design process for new toys. Using the Unity engine which is used in many video games, Krisman brought the CAD model for Imaginext’s BatBot project to life. The design team donned their VR headsets and were able to play around with a virtual prototype of the toy. Unity’s physics and incredibly accurate geometry allowed the team to explore the movement of the toy’s mechanical parts and to test its tolerances in order to make whatever changes were necessary.

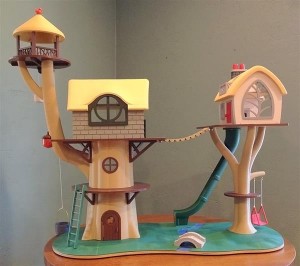

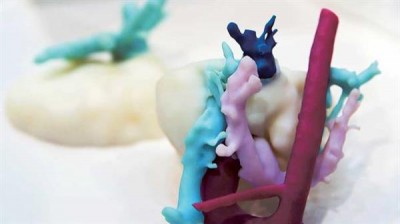

For Berkheiser, the most enjoyable and rewarding part of the VR experience was the chance to get inside the minds of the children that would be using their product. “I’m [wearing VR], and John says, do you want to see what if feels like if you were four years old and standing there?”, he recalls. ‘’It was a pretty magical moment. And I hadn’t felt like looking at a toy like that before VR.” The 28-inch BatBot Xtreme with its impressive wingspan, tracheal elevator, huge fists, and vocal changer that can turn a child’s voice into that of a crime-fighting superhero, is now available to pre-order and will be in stores in the fall.

According to Berkheiser, it is just the first of many toys that will be tested using VR techniques, which could soon become the industry standard. “I might feel comfortable moving all the way to first plastic [just from] looking at something virtual,” he says. “In the past, I would have never dreamed that. And you know, if there’s something simple and it’s not a complex product, I could see going all the way down the line [into production].” If a company as significant as Fisher Price is using VR to speed up the design process, it can only be a matter of time before other industries besides toy manufacturing will be making use of the technology. With even 3D printing now being superseded as a rapid prototyping solution, the manufacturing world looks to be on the brink of a major transformation.